Engine technical parameters

The technical parameters of Yanmar 3TNV88 engine are as follows:

- Displacement: 0.9 liter (883 cc)

- Bore diameter: 88 mm

- Stroke: 90 mm

- Number of cylinders: 3 cylinders

- Fuel type: diesel

- Cooling method: water cooling

- Maximum power: 26.1 kilowatts (35 horsepower)

- Maximum torque: 82.3 N·m (60 lb·ft)

- Maximum speed: 3000 RPM (no load)

These technical parameters can help users understand the basic specifications and capabilities of the Yanmar 3TNV88 engine. It is a small diesel engine suitable for various applications such as wheeled tractors, small loaders, excavators, etc. Specific applications and performance will also be affected by specific mechanical equipment configuration and application environment.

Application scope

Yanmar 3TNV88 engine is suitable for the following application areas:

- Small excavators: The Yanmar 3TNV88 engine performs well on small excavators, providing reliable power output and efficient working capabilities. This engine is suitable for a variety of excavation tasks such as earthmoving, trenching, excavation of foundation pits, etc.

- Wheel loader: Yanmar 3TNV88 engine can be used in small wheel loaders to provide them with powerful power and driving force. This allows the loader to have fast loading and unloading capabilities and high earth-moving capabilities, and is suitable for stacking materials, loading and unloading cargo, leveling construction sites, etc.

- Wheeled tractors: Yanmar 3TNV88 engine is suitable for small wheeled tractors, providing them with sufficient power and torque to complete agricultural tasks such as farming, raking, and handling.

- Mechanical equipment: Yanmar 3TNV88 engine can also be used in various small mechanical equipment, such as small generators, water pumps, compressors, etc. It can be a reliable source of power for these devices.

It should be noted that the specific application scope also depends on the specific mechanical equipment installed and matched as well as the use environment. Therefore, it is recommended that when selecting the Yanmar 3TNV88 engine, further consultation and confirmation with the equipment manufacturer or dealer is recommended to ensure suitability and performance requirements are matched.

Engine care and maintenance

For the maintenance and upkeep of the Yanmar 3TNV88 engine, here are some suggestions:

- Regularly change the engine oil and filter: Regularly changing the engine oil and filter is the key to maintaining healthy engine operation. Follow appropriate change intervals and use the correct specifications of oil and filter according to the owner’s manual or recommendations.

- Clean the air filter: Cleaning and replacing the air filter is also important. Check and clean the air filter regularly to ensure it is effectively filtering the air and preventing dust and particles from entering the engine.

- Keep the cooling system clean and coolant levels normal: Check coolant levels regularly and make sure the engine cooling system remains clean. Avoid coolant leaks and engine overheating.

- Check and replace the fuel filter: Check the fuel filter regularly and replace it as necessary. A clean fuel filter prevents impurities from entering the fuel system and protects the engine.

- Regularly check the transmission system and other connecting parts: Regularly check the tightening of the transmission system and other connecting parts, and adjust and replace them if necessary. Ensure the normal operation of the transmission system and the reliability of the connection.

- Pay attention to engine operation: Pay close attention to engine operation, including noise, vibration and emissions. If any abnormalities are found, troubleshoot and repair them promptly.

- Seek professional repair and service: If you are not sure how to properly maintain and service your Yanmar 3TNV88 engine, or if you need more complex repairs and services, please seek help from a professional repairman or dealer.

Please note that the above recommendations are general and do not represent all maintenance and upkeep requirements. Specific maintenance and repair operations should be carried out according to the specific specifications and user manual of the Yanmar 3TNV88 engine.

Troubleshooting and repair

When a Yanmar 3TNV88 engine fails, here are some common troubleshooting and repair suggestions:

- Check the fuel supply system: If the engine cannot start normally or there is a fuel supply problem, first check whether the fuel supply is normal, including checking whether the fuel filter is blocked and whether the fuel pump is working properly.

- Check the ignition system: If the engine cannot ignite or ignition is abnormal, check the ignition system, including checking whether the spark plug is normal, whether the ignition wire is damaged, whether the ignition coil is normal, etc.

- Clean/replace the air filter: If the engine has emission problems, low power, or unstable operation, you can check whether the air filter is clogged or has excessive dirt, and clean or replace the air filter.

- Check the cooling system: If the engine is overheated or undercooled, check whether the cooling system is operating normally, including checking whether the coolant level and flow are normal, and whether the coolant pump is working properly.

- Check the exhaust system: If the engine exhaust is abnormal or the exhaust pipe emits black smoke, check whether the exhaust system is blocked or the exhaust pipe is damaged.

- Check the lubrication system: If the engine has insufficient lubrication or abnormal noise, check the lubrication system, including checking the oil level and whether the oil pump is working properly.

- Seek professional repair and service: For more complex faults or situations where important parts need to be replaced, it is recommended to seek the help of professional maintenance personnel or dealers to ensure correct troubleshooting and repair.

Please note that the above suggestions are for reference only and do not cover all failure scenarios. Specific troubleshooting and repair recommendations should be determined based on the specific failure symptoms and Yanmar 3TNV88 engine requirements. If you are unsure about troubleshooting and repairs, consult a professional.

Engine technology upgrade

For the technical upgrade of the Yanmar 3TNV88 engine, the following are some possible options and suggestions:

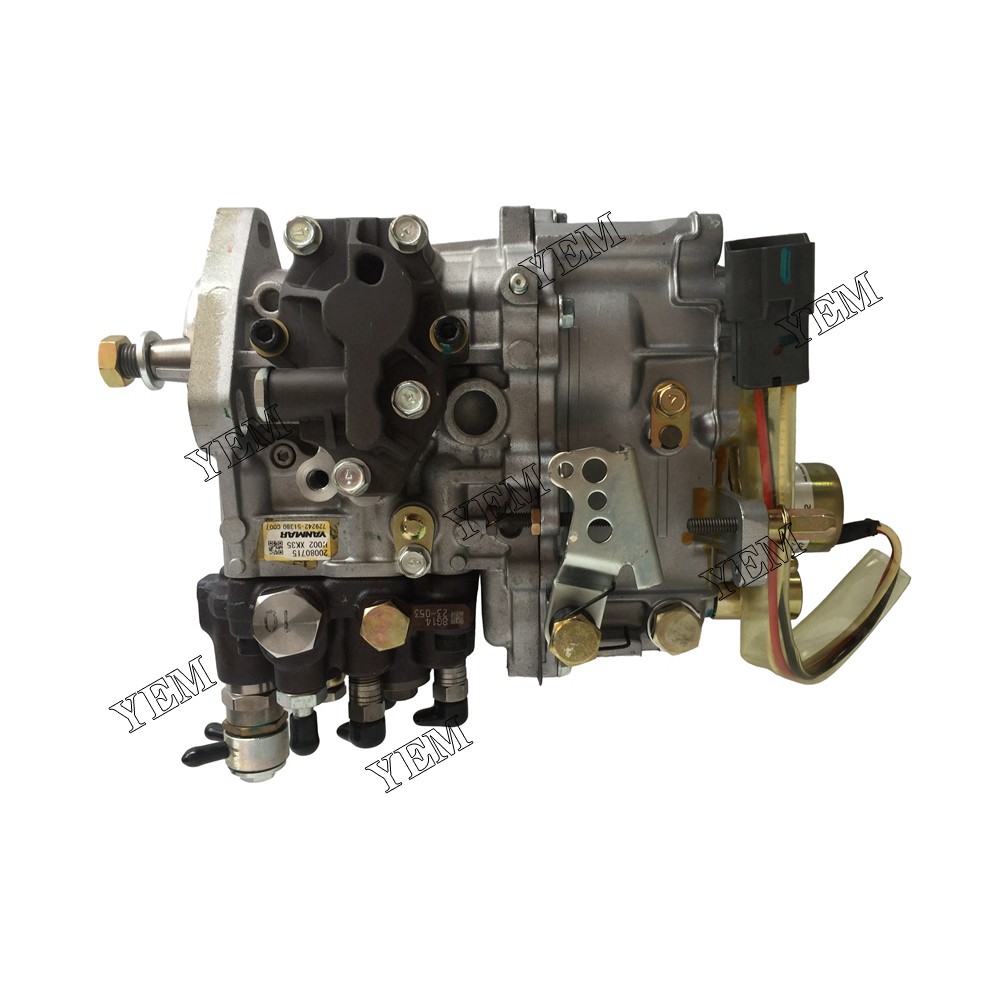

- Fuel system optimization: The combustion efficiency and fuel economy of the engine can be improved through optimization of the fuel system. This can include improving the fuel injection system, adjusting the size and angle of the injectors, optimizing the fuel supply method, etc.

- Turbocharging system: Adding a turbocharging system can increase the engine’s output power and torque, further improving engine performance. This can be achieved by installing a turbocharger and associated boost ducting.

- Efficient heat dissipation system: Improving the engine’s heat dissipation system can effectively reduce the engine’s operating temperature and improve the engine’s thermal efficiency and life. This may include optimizing radiator design, increasing cooling area, improving air ducts and ventilation systems, etc.

- Electronic control system upgrade: The modern electronic control system can provide more precise control and adjustment for the engine. More advanced engine management and optimization can be achieved by upgrading the electronic control unit (ECU) and associated sensors.

- Emission control technology improvement: As emission standards improve, you can choose to improve the engine’s emission control technology. This may include adding emission control devices (such as particulate traps or urea injection systems), optimizing exhaust gas recirculation (EGR) systems, etc.

- Application of energy-saving technology: In technology upgrades, energy-saving technologies, such as start-stop systems, energy recovery systems, etc., can be considered to further improve fuel economy and environmental performance.

Please note that technical upgrades require professional engineering and appropriate equipment. Before undertaking any engine technology upgrade, it is recommended to consult with the engine manufacturer or a professional engineer to ensure the feasibility and effectiveness of the upgrade solution.

Contact us

Our YEM team is fully dedicated to delivering outstanding service and support. Should you have any inquiries or require any assistance, please don’t hesitate to get in touch. We’re readily available through the following communication channels:

Rest assured, we are committed to providing timely and comprehensive assistance, and we eagerly look forward to helping you with any questions or concerns you may have.