Common troubleshooting

The following are common troubleshooting methods for the D722 engine used in the Kubota K008-5 excavator:

- Engine cannot start:

- Check the fuel supply: Make sure there is enough fuel in the fuel tank, check if the fuel filter is clean, and check if the fuel pump is working properly.

- Check the power supply: Check whether the battery is fully charged, check whether the starter and ignition system are working properly.

- Ensure starting conditions: Check that the correct preheat button is pressed before starting (if applicable) and keep the throttle closed before starting.

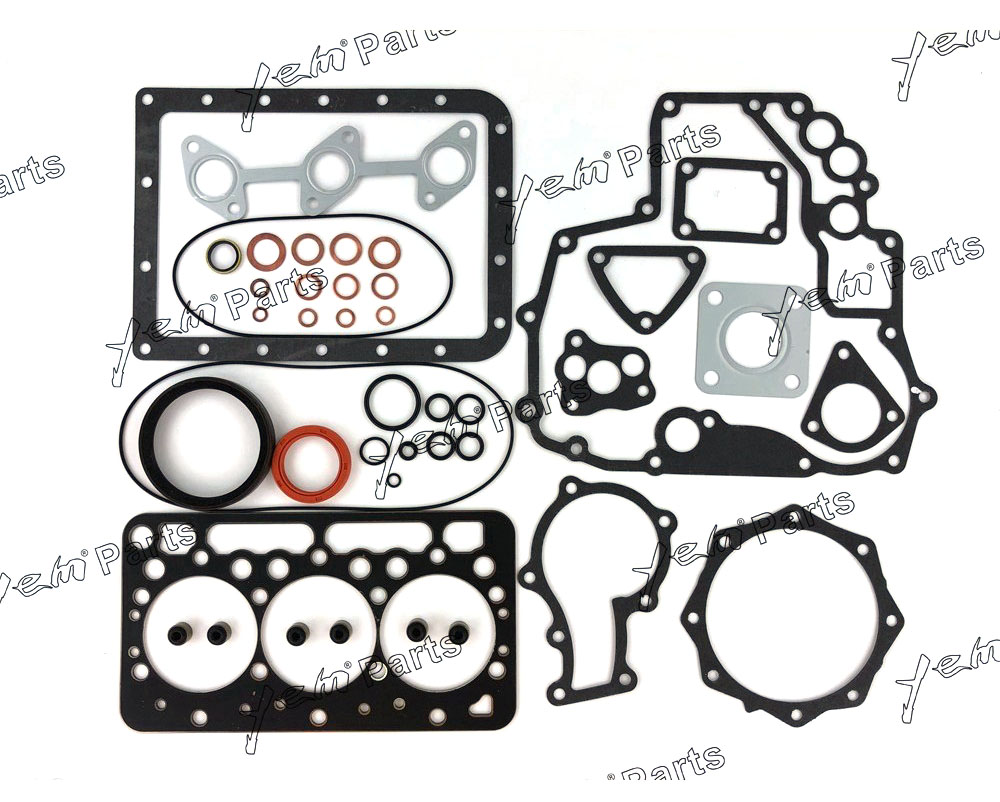

- Engine oil leakage:

- Check seals: Check the seals of various parts of the engine, such as oil pan seals, cylinder head seals, etc. If leakage is found, damaged seals should be replaced promptly.

- Observe the location of oil leakage: Determine the source of oil leakage by observing the location of oil leakage. It may involve the oil pan, valve cover, oil filter, etc.

- Pay attention to the oil level: Make sure the engine oil level is within the normal range. Too much or too little oil may cause oil leakage.

- Abnormal exhaust:

- Check the exhaust pipe: Check the exhaust pipe for odor, abnormal color, and abnormal noise. This may be caused by abnormal fuel, oil quality, or problems with the exhaust system.

- Check the fuel injector: Check whether the fuel injector is clean and inject fuel normally. The injector can be cleaned or replaced.

Engine maintenance

The following are maintenance recommendations for the D722 engine used in Kubota K008-5 excavator:

- Change engine oil and filter:

- Regular oil changes are an important step in keeping your engine running properly. Refer to your owner’s manual to determine oil change intervals and recommended oil types.

- Also replace the oil filter to ensure that waste and contaminants do not re-enter the engine.

- Clean the air filter:

- Clean or replace the air filter regularly to ensure that the engine can properly inhale clean air. A clogged air filter can affect combustion efficiency and increase engine wear.

- Check the coolant:

- Check the coolant level and coolant concentration regularly. Make sure there is enough coolant in the cooling system and replace it according to the coolant type and replacement interval recommended in the owner’s manual.

- Fasten bolts and pipes:

- Regularly check the fastening bolts and pipes on the engine to ensure they are securely connected. Loose bolts and lines can lead to oil leaks, wear and other potential problems.

- Clean the fuel system:

- Clean the fuel system regularly to prevent the accumulation of carbon deposits and contaminants. Fuel system cleaners can be used to remove carbon and deposits.

- Check spark plugs regularly:

- Check and replace spark plugs regularly to ensure good ignition system operation. Check the electrode gap and adjust as necessary according to the instructions in the user manual.

Please note that these are only general maintenance recommendations. Specific maintenance plans and operating steps should be carried out according to the user manual and maintenance guide provided by the manufacturer. At the same time, regular maintenance and entrusting professional technicians to perform inspections and repairs can ensure the long-term reliability and good operating condition of the engine.

Lubrication system maintenance

Maintenance recommendations for the D722 engine lubrication system used by Kubota K008-5 excavator:

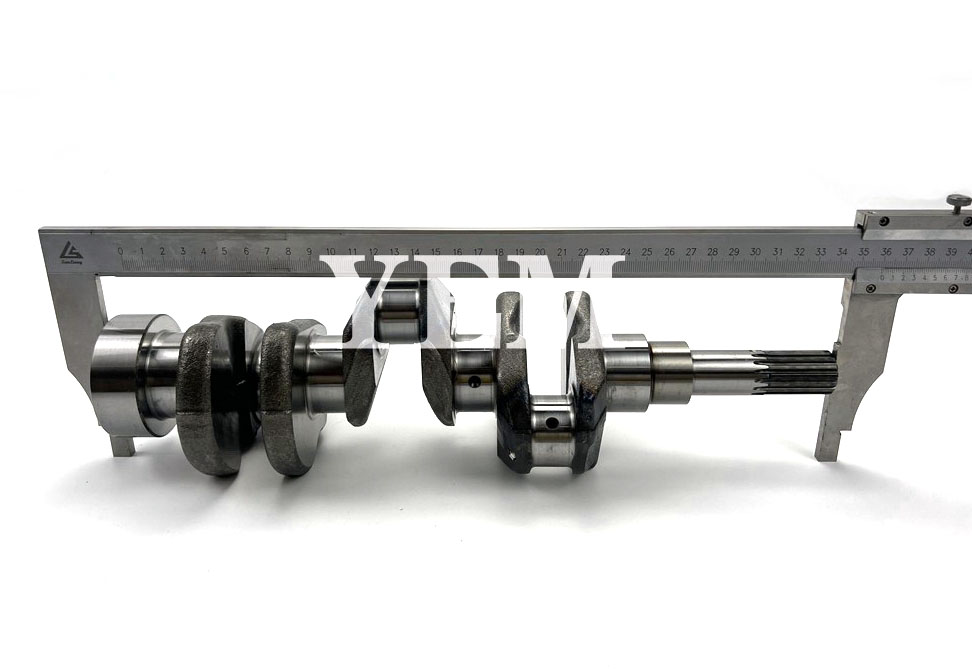

- Change engine oil:

- Regularly changing the engine oil is a necessary step to keep the engine running properly. Failure to follow oil change recommendations can cause damage to the lubrication system and engine.

- Carry out oil change unit and cycle planning according to the requirements of the user manual.

- Replace the oil filter:

- Replace the oil filter to ensure that waste and contaminants in the oil do not re-enter the lubrication system.

- Perform filter element screening and replacement cycles according to the instructions in the user manual.

- Clean the lubricating oil system:

- Clean the lubricating oil system regularly to ensure that the engine does not fail due to excessive condensation, dirt and other impurities.

- Refer to the user manual, observe the fault indicators, clear the fault, and replace the non-luminous or damaged materials to ensure the normal operation of the lubrication system.

- Lubricate the fuel pump:

- The fuel pump is an important part of the engine and should be lubricated regularly to ensure its normal operation.

- Every time you change the engine oil, remember to lubricate the oil pump to ensure it is working properly.

Please note that lubrication system maintenance is crucial to the long-term reliable performance of the engine. Regular maintenance can extend the service life of the lubricating oil and ensure the normal operation of the engine. The engine lubrication system needs to be better serviced according to the instructions in the user manual. If you have problems, please contact the relevant technicians for troubleshooting.

Fuel system maintenance

The following are maintenance recommendations for the D722 engine fuel system used in Kubota K008-5 excavator:

- Replacement of fuel filter:

-Replace fuel filters regularly to prevent contaminants from entering the fuel system.- Carry out the replacement cycle of the filter element according to the requirements of the user manual.

- Add appropriate fuel additives:

- Use approved fuel additives to help clean the fuel system and provide better combustion performance.

- Follow the additive manufacturer’s recommendations and add the appropriate dosage when refueling.

- Ensure good fuel quality:

- Use good quality fuel that meets specifications to ensure proper engine operation.

- Avoid mixing impurities or moisture in the fuel, which may cause damage to the fuel system.

- Check the fuel pump and injectors:

- Check the fuel pump and injectors regularly to make sure they are working properly and clean or adjust them to maintain optimal performance.

- If any abnormalities are found, such as oil leakage from the pump or clogged fuel injector, please repair or replace the damaged parts in time.

- Clean the fuel system:

- Perform fuel system cleaning regularly to remove carbon deposits and impurities.

- You can use special fuel system cleaning agent and follow the product instructions for cleaning.

Please note that fuel system maintenance is critical to proper engine operation and durability. Make sure to follow the recommendations and maintenance schedule in the owner’s manual and seek the advice and support of a professional technician when needed.

Cooling system maintenance

The following are maintenance recommendations for the D722 engine cooling system used on the Kubota K008-5 excavator:

- Check the coolant level:

- Always make sure the coolant level is within the proper range. If the water level is too high or too low, it can cause engine problems.

- Please be careful not to have too much or too little coolant, and fill or drain it appropriately according to the requirements of the user manual.

- Check the water pump:

- Check the water pump regularly to ensure it is pumping coolant effectively at all times.

- Check whether the water pump is leaking or producing other abnormal behaviors. If so, contact technicians in time for troubleshooting and repair.

- Clean the radiator:

- Clean the radiator regularly to ensure it is properly ventilated. A clogged radiator affects engine cooling, causing the engine to overheat.

- Use compressed air or detergent to gently remove dust and dirt from the radiator surface.

- Replace the coolant:

- Change coolant regularly to ensure its performance and protect the engine. Good quality coolant keeps your engine stable under various temperature conditions.

- Refer to the owner’s manual for coolant brand and replacement intervals.

- Check the coolant lines:

- Check the coolant lines regularly to make sure they are not leaking or damaged. Broken pipes may cause coolant to leak, affecting the normal operation of the engine.

Please note that cooling system maintenance is critical to proper engine operation. Regular maintenance and inspection of the cooling system can extend the service life of the engine and ensure excellent engine performance in a variety of temperature conditions. Once again, we remind you to operate according to the recommendations in the user manual. If you encounter any problems, please consult relevant technical personnel for advice in a timely manner.

Control system maintenance

The following are maintenance recommendations for the Kubota K008-5 excavator control system:

- Clean and protect the machine control panel:

- Regularly clean and protect the buttons, switches and displays on the machine control panel to prevent dust, moisture and other contaminants from affecting the normal operation of the system.

- Use special cleaner and soft cloth to clean the machine control panel.

- Update software:

- Regularly update system software and firmware to ensure consistent, stable and reliable operation of the equipment.

- If you need to update the software, please follow the instructions in the user manual.

- Protect wires and cables:

- Inspect and protect wires and cables to ensure they are not damaged by cutting, crushing or friction.

- Frequently check the connection points of wires and cables to make sure they are in a tight and stable condition.

- Check sensors and actuators regularly:

- Check sensors and actuators to ensure proper operation. Those actuators operating under harsh conditions are particularly in need of inspection.

- If you find that the sensor or actuator is faulty, please contact technicians in time for troubleshooting and repair.

- Ensure power supply:

- Ensure equipment power supply is smooth, stable and reliable to prevent equipment from causing malfunctions such as blocking current or affecting system control.

- Ensure that the power source used by the machine meets the required standards to ensure its proper operation.

Please note that the normal operation of the control system is critical to the operation and safety of the machine. Regular maintenance, inspection and protection of the control system can extend the service life of the machine and ensure its stable and safe operation. Please operate and maintain according to the requirements of the user manual. If there is any problem, please contact professional technicians in time for troubleshooting and repair.