Technology Introduction

The technical introduction of Kubota engine E series is as follows:

- Engine type: Kubota engine E series is an internal combustion engine. According to different application fields and needs, it can be divided into two types: gasoline engine and diesel engine.

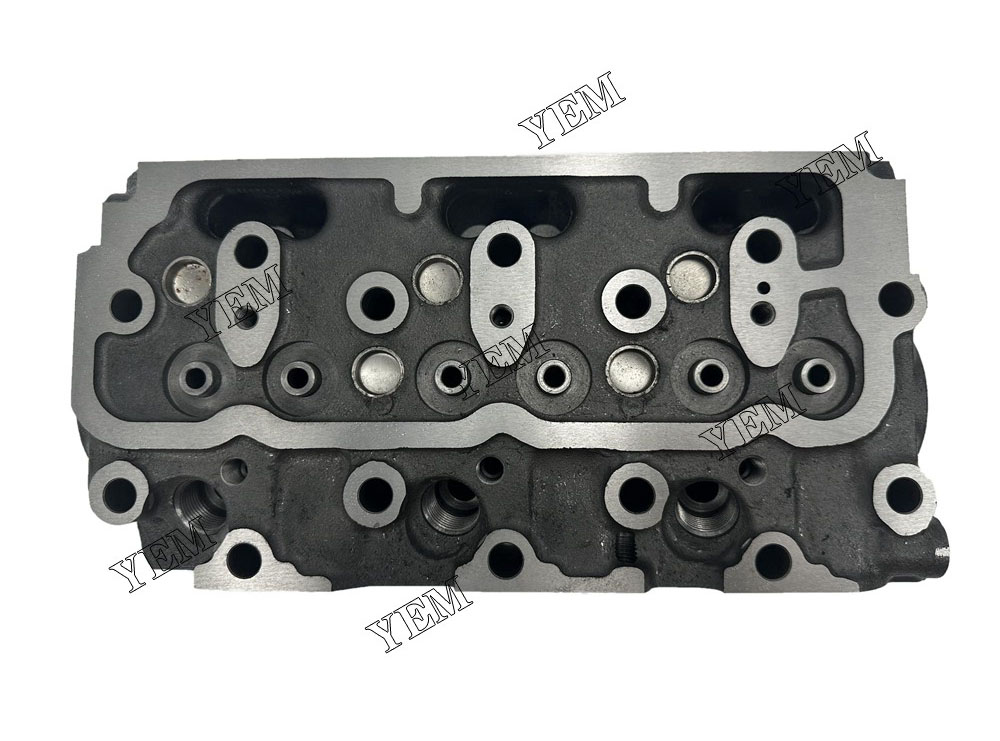

- Engine structure: Kubota engine E series adopts in-line or V-shaped multi-cylinder structure. Multi-cylinder engines can provide greater power and torque output to meet different power needs.

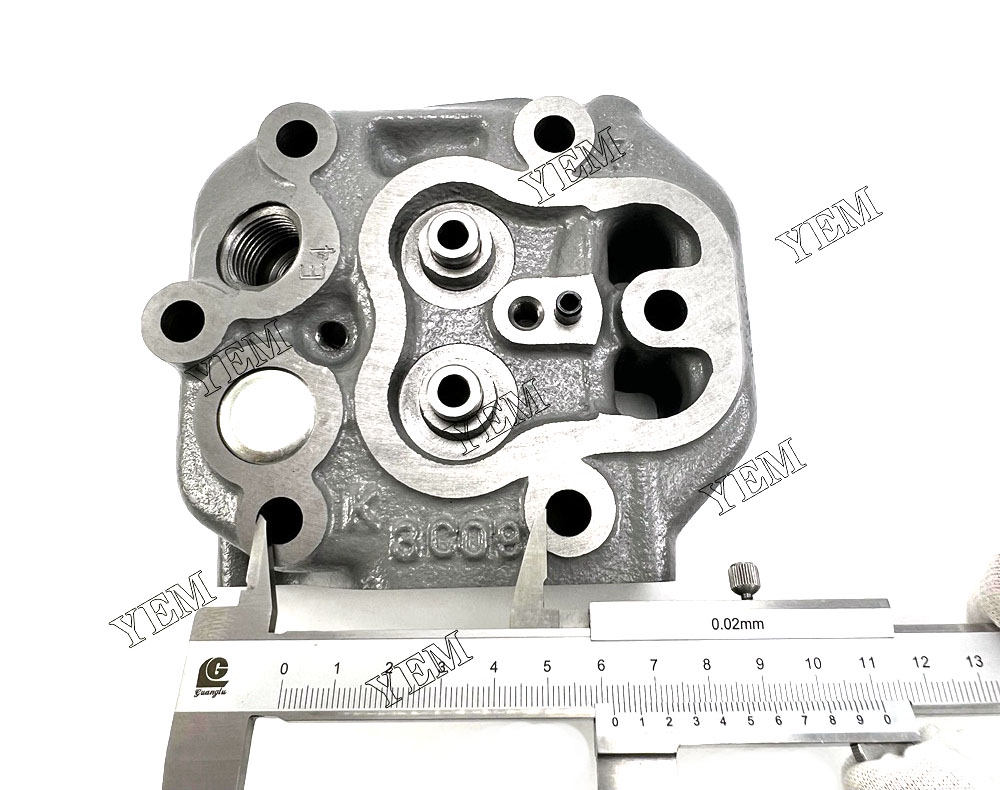

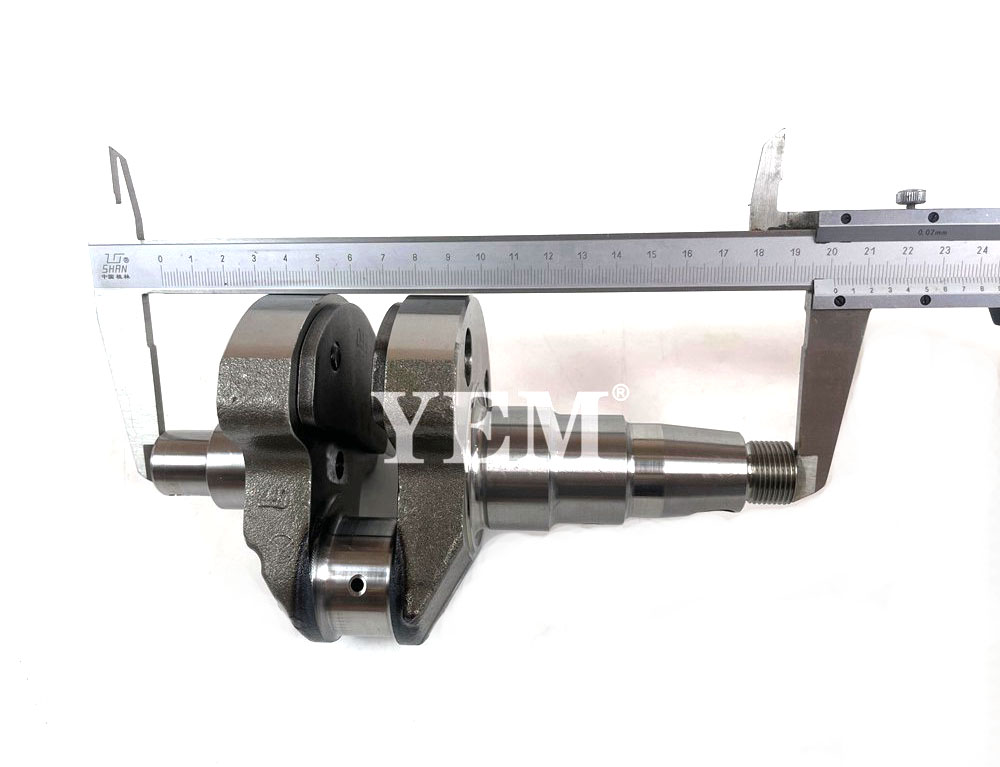

- Bore and stroke: The bore and stroke of the engine determine the amplitude of piston movement, which directly affects the engine’s displacement and performance. The bore and stroke of the Kubota engine E series are reasonably designed to achieve efficient combustion and power output.

- Combustion system: Kubota engine E series adopts advanced combustion systems, such as direct injection technology and premixing technology. These technologies can improve fuel combustion efficiency, reduce the production of emissions, and improve engine power performance.

- Exhaust system: The exhaust system of the Kubota engine E series has been optimized and designed to effectively discharge the exhaust gas generated by combustion and reduce the content of emissions. These systems include components such as intake pipes, exhaust pipes, catalytic converters, and more.

- Cooling system: Kubota engine E series is equipped with an effective cooling system to ensure that the engine maintains a suitable temperature during operation. The cooling system consists of water pumps, radiators, fans and other components, which can effectively reduce engine heat.

- Electronic control: Kubota engine E series adopts an advanced electronic control system to monitor and control the working status of the engine through sensors and control units. This electronic control system can adjust parameters such as ignition timing and fuel injection volume in real time to improve engine efficiency and performance.

- Energy saving and environmental protection features: Kubota engine E series focuses on energy saving and environmental protection. Through optimized design and advanced technology, the engine can provide higher combustion efficiency and thermal efficiency, reducing energy consumption and greenhouse gas emissions.

Application areas and markets

The Kubota engine E-Series has a wide range of applications in a variety of applications and markets.

- Agricultural machinery: Kubota engine E series is suitable for various agricultural machinery, such as farming machinery, agricultural tractors, sprinkler irrigation machines, etc. These engines provide powerful power output and reliable performance to help farmers complete a variety of farm operations.

- Construction machinery: Kubota engine E series is suitable for various construction machinery, such as excavators, bulldozers, loaders, road rollers, etc. These engines can provide high torque and excellent power response, adapting to various complex construction environments and task requirements.

- Ships: Kubota engine E series can also be used in various ships, including fishing boats, speedboats, yachts, etc. These engines are stable, reliable, cost-effective and ensure that the ship can provide sufficient power when running on the water.

- Generator sets: Kubota engine E series can also be used in generator sets to provide stable power for residential and industrial areas. These engines feature efficient combustion systems and stable performance to reliably provide continuous power output.

Kubota engine E series has a good reputation and market share in the global market. Its excellent performance, reliability and fuel economy make the Kubota engine E series popular among users. Kubota not only has a wide range of applications in the Japanese market, but also cooperates with various equipment manufacturers globally to provide engine solutions in fields such as agriculture, engineering, marine and power generation.

Maintenance and Care Guide

The more common Kubota engine E series maintenance and service guidelines are as follows:

- Change the engine oil: Regularly changing the engine oil can ensure that the engine maintains good lubrication and cleanliness and prolongs the life of the engine. The intervals between oil changes should be based on frequency of use and working environment. Generally, it is recommended to perform an oil change every hour for some time before the engine starts running. During subsequent use, it can be replaced every 50 to 100 hours. Use the type of oil recommended by the machine manufacturer and read the owner’s manual carefully before changing.

- Replace the filter: In addition to the oil filter, the air and fuel filters also need to be replaced regularly. The air filter prevents dust and particles from entering the engine, and the fuel filter filters out dirty impurities in the oil. Replacement time should be based on filter usage, usually every 50 to 100 hours.

- Check the coolant: Coolant is a critical component in maintaining engine temperature while the engine is running. Therefore, coolant levels and quality should be checked regularly. The quality of the coolant should meet the manufacturer’s recommendations, and antifreeze should be injected at low temperatures to avoid a burst tank.

- Adjust oil pressure: Oil pressure affects the lubrication effect of the engine. Oil pressure needs to be checked regularly and adjusted as necessary. Checking oil pressure requires specialized equipment, so it is recommended to seek an experienced technician for this task.

- Check the belt: The engine belt may wear and fatigue during operation, resulting in unstable operation or damage. The condition of the belt should be checked regularly and replaced if necessary.

- Maintain electronic systems: When the electronic control system fails, the engine may not work properly. The working status of the electronic control system should be checked regularly, and the connections and status of components such as wires, sensors and control units should be checked.

Please note that these are general maintenance and service guidelines for the Kubota Engine E Series. Different engine models may require different maintenance procedures and schedules. It is recommended to consult the manufacturer’s detailed operating instructions or seek help from an experienced technician to keep your engine in top condition.

Troubleshooting and bug fixing

When encountering faults and issues with the Kubota engine E-Series, here are some common steps for troubleshooting and fault repair:

- Check the fuel supply: If the engine won’t start or keep running properly, first check for fuel supply problems. Make sure there is enough fuel in the fuel tank, check whether the fuel pipes and filters are clogged, and whether the fuel pump is working properly.

- Check the ignition system: If the engine won’t start or run smoothly, there may be a problem with the ignition system. Check whether the spark plug is dirty or worn and whether it needs to be replaced; check whether the ignition coil and ignition wire are connected normally; ensure the correct ignition timing.

- Check the air supply: If the engine is running erratically or experiencing low power output, you can check for air supply problems. Check whether the air filter is dirty and needs to be replaced; make sure the air intake pipe is clear.

- Check the cooling system: If the engine overheats or is not cooled enough, performance degradation or damage may occur. Check the level and quality of engine coolant to make sure there are no leaks or blockages in the cooling system.

- Check the transmission system: If the engine power output is abnormal or there is abnormal noise in the transmission, there may be a problem with the transmission system. Check the condition of the drive belt or chain to make sure it is not worn or loose; check to see if the transmission needs lubrication or replacement.

- Contact professional technical support: If the above troubleshooting steps fail to solve the problem, or more in-depth troubleshooting and repair are required, it is recommended to contact Kubota authorized technical support or dealer. They can provide more specialized help and advice and may need to carry out more complex troubleshooting and repairs.

For specific troubleshooting and fault repair of the Kubota engine E series, it is recommended to refer to the official operating manual and maintenance guide provided by Kubota or contact official technical support for detailed and accurate information.

New products and innovative technologies

Kubota has been continuously innovating and developing new products and technologies. Here are some examples in recent years:

- EGR cooler technology: Kubota uses EGR (exhaust gas recirculation) cooler technology to recirculate exhaust gas back into the engine to reduce emissions and contribute to energy conservation and environmental protection.

- Engine electronic control technology: Kubota adopts advanced engine electronic control technology, allowing the engine control unit to intelligently manage and monitor various factors, such as fuel proportioning, air intake and emission control to improve efficiency and reduce emissions.

- Lightweight design: Kubota focuses on lightweighting during the design process, using advanced materials and structural design to reduce the weight of the engine, thereby improving performance and fuel efficiency.

- Electrification technology: Kubota is developing and promoting electrification technology to more closely integrate engines and electrical systems to improve reliability, efficiency, environmental protection and intelligence.

- Management system: Kubota is actively developing and promoting management systems to help customers better manage and monitor their engine equipment, predict possible failures and improve maintenance efficiency.

These are several directions Kubota is taking in terms of new products and technologies. In the future, Kubota will continue to be committed to technological innovation and continuous improvement of product and service quality to provide customers with more and better choices.

Industry news and trends

As an AI assistant, I cannot provide real-time industry news and trends. However, here are some common news and trends in the current industry. You can get more detailed and real-time information by consulting relevant news sources:

- Sustainable development: Sustainability is an important concern in the current industry. Many companies are making progress in their efforts to reduce resource consumption, reduce emissions, promote a circular economy and adopt clean energy.

- Digital transformation: The industry is facing a wave of digital transformation. Technologies such as the Internet of Things (IoT), big data analysis, artificial intelligence, and machine learning are being widely used in areas such as production, supply chain, and equipment management to improve efficiency, quality, and intelligence.

- Automation and robotics: Automation and robotics are increasingly used. Automated production lines and robotic systems can improve production efficiency, reduce costs, and reduce the need for manual labor.

- New energy and electrification: As the demand for environmentally friendly and renewable energy increases, so does the industrial interest in new energy and electrification. Electric vehicles, renewable energy generation and energy storage technologies are all hot topics right now.

- Artificial Intelligence Application: The application of artificial intelligence is developing rapidly in the industrial field. It can be used for predictive maintenance, quality control, automated decision-making, etc., providing enterprises with higher efficiency and better decision-making support.

Please keep in mind that these are just some common industry news and trends, and specific news and trends will change over time. It is recommended that you pay attention to professional news media, industry reports and market research in the industry to obtain the latest and accurate information.