Perkins engine accessories introduction

Perkins engine accessories are parts designed and produced specifically for Perkins engines to provide superior performance, reliability and durability to meet the needs of a variety of applications and operating conditions.

Perkins engine parts cover a wide range of component types, including pistons, crankshafts, cylinder liners, valves, fuel systems, exhaust systems, ignition systems, and more. Each accessory is precisely calculated and rigorously tested to ensure it meets Perkins engine specifications and standards.

One of the advantages of Perkins engine parts is their high quality and durability. As a well-known engine manufacturer, Perkins focuses on product quality and reliability. Therefore, accessories use high-quality materials and advanced manufacturing processes, and undergo strict quality control to ensure that they provide excellent performance under various working conditions.

Additionally, Perkins engine accessories offer flexibility and compatibility. They are suitable for different models and types of Perkins engines, including industrial, commercial and agricultural applications. Whether for generators, farm machinery or commercial vehicles, Perkins engine parts have something to suit every need.

Purchasing Perkins engine parts is also a smart choice. They tend to be competitively priced and economical to use and maintain over the long term. In addition, Perkins provides a global after-sales service and support network to ensure that customers receive professional support and guidance when purchasing, installing and maintaining accessories.

In summary, Perkins engine parts deliver superior performance, reliability and durability, ensuring that your Perkins engine performs well and extends its service life in a variety of applications. Whether as replacements or upgrades, Perkins engine parts will bring reliable and efficient power to your machinery.

Accessory types and applications

There are many types of Perkins engine accessories. Here are some common accessories and their applications:

- Piston and piston rings: The piston is one of the most important parts of the engine. It helps control the air flow and pressure in the combustion chamber and works in synchronization with the crankshaft. Piston rings are used to control pressure between cylinders and protect the piston.

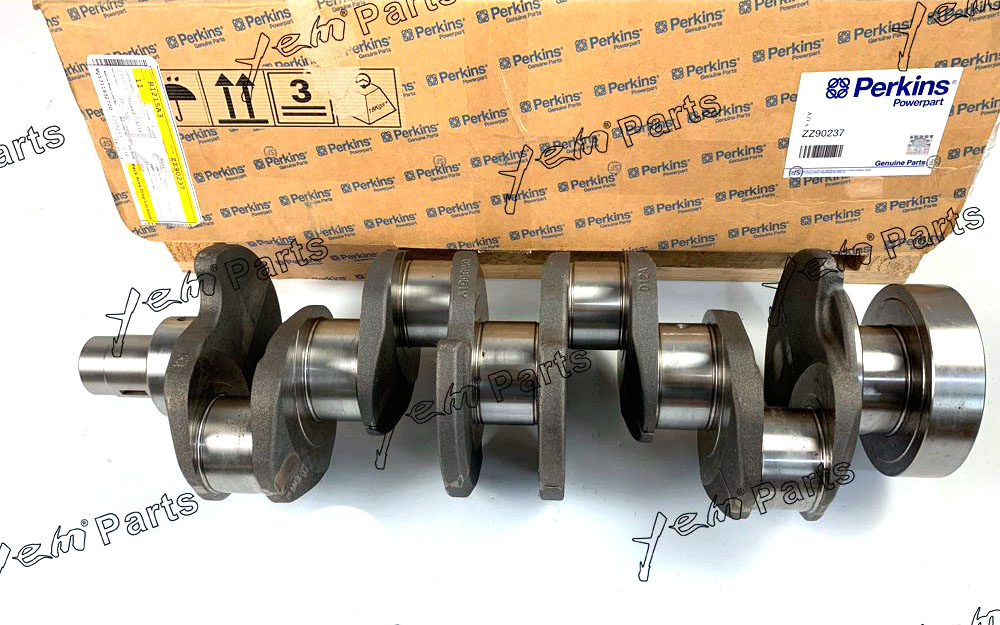

- Crankshaft: The crankshaft converts pressure from the pistons into rotational power and is one of the most important moving parts in the engine. Its quality and manufacturing process are critical to engine performance.

- Cylinder liner and piston pin: The cylinder liner is located in the cylinder and provides the direction of movement of the piston. The piston pin connects the piston to the crankshaft and ensures that they work in sync.

- Valve: The valves manage the flow of air and fuel in the engine, and they need to be cleaned regularly to maintain a stable combustion process.

- Fuel system: The fuel system includes fuel pump, fuel injector, fuel filter and pressure regulator, etc. These components work in harmony to manage the flow of fuel within the engine and ensure that it enters the combustion chamber at the right time and in the right amount.

- Exhaust system: The exhaust system includes exhaust manifolds, exhaust pipes, catalysts, mufflers, etc. These components work in coordination to manage the exhaust gases generated in the engine.

- Ignition system: The ignition system includes ignition coil, spark plug, ignition control module, etc. They manage the ignition and combustion of fuel to produce the energy needed by the engine.

- Radiator and Water Pump: These components work in harmony to manage the flow of coolant to maintain the engine’s operating temperature.

Perkins engine accessories are used in a variety of industrial, commercial and agricultural applications, depending on the vehicle type and equipment needs. For example, Perkins engines are used in a wide range of industrial applications, including generator sets, pumping stations, cranes and construction machinery. In the agricultural field, Perkins engines are widely used in tractors, harvesters and planters. No matter the application, using the right Perkins engine parts can keep your equipment running smoothly and extend its service life.

Buying guide and selection advice

If you need to buy Perkins engine parts, here are some buying guides and selection suggestions to help you make the right decision:

- Know your equipment: Before purchasing Perkins engine parts, you should carefully understand the model and specifications of your equipment. Since different models of equipment require different parts, it’s important to know your equipment.

- Quality first: Quality should be your primary consideration when choosing Perkins engine parts. As a world-renowned engine manufacturer, Perkins has gained wide recognition for the quality of its accessories, excellent performance and durability. Purchasing quality accessories ensures reliable operation of your equipment.

- Reasonable price: Price is one of the factors to consider when purchasing any product. Perkins engine parts are often competitively priced, and their performance and durability will allow you to save even more during your purchase. A balance of quality and price should be considered in order to get the best value.

- Make a differentiated comparison: Before purchasing, it is recommended that you make a differentiated comparison to choose the best option. In addition to using the official website, consider checking out other available resources such as accessory sellers, forums, and social media platforms to get opinions and advice on different accessories.

- Learn more about after-sales service: Before purchasing, make sure you understand the after-sales service support, such as parts delivery time, return and exchange policy, and fault repair support. Perkins has a global customer service and support network that can provide you with advice and guidance on standards and best practices for Perkins engine parts.

In summary, choosing the right Perkins engine parts is important because it affects the performance, durability, and safety of your equipment. Purchasing Perkins engine parts with excellent quality, reasonable prices, and excellent after-sales service will ensure the stable operation of your equipment and extend its service life.

Installation and maintenance recommendations

The correct method of installing and maintaining Perkins engine accessories is key to ensuring proper engine operation and extending its service life. Here are some installation and maintenance suggestions:

- Follow Official Guidelines: Always follow official installation guidelines and maintenance manuals when installing and maintaining Perkins engine accessories. These manuals provide detailed steps and precautions to ensure proper installation and maintenance.

- Use the correct tools and equipment: It is important to use the correct tools and equipment during installation and maintenance. Use specific tools and equipment recommended by Perkins to ensure proper removal and installation of parts to avoid damage or incorrect installation.

- Regular inspection and maintenance: It is very important to carry out regular inspection and maintenance of engine accessories to ensure their good condition and performance. Regular inspections involve cleaning, lubricating, replacing worn parts, etc. to ensure that accessories are working in good condition.

- Pay attention to details and special requirements: Perkins engine accessories may have some special installation and maintenance requirements, such as torque requirements, lubrication requirements, etc. Please make sure you are fully aware of these details and follow the requirements.

- Handle faults and repair them promptly: If any faults or problems are discovered, it is crucial to handle them promptly and fix them. Delaying treatment can result in greater damage and costs.

- Establish records and tracking: It is recommended to record information such as installation date, maintenance records, and accessory replacement history. This helps track maintenance history and perform necessary maintenance and replacement in a timely manner.

- Seek professional support: If you are not sure how to install or maintain Perkins engine accessories, or encounter complex fault conditions, it is recommended to seek professional support and consultation. Perkins offers an extensive after-sales service and support network that can provide you with professional advice and guidance.

In summary, correct installation and maintenance are key to ensuring the normal operation of Perkins engine parts and extending their service life. Please always follow official guidelines and pay attention to details, handle failures promptly, and perform regular inspections and maintenance. Please feel free to seek professional support if needed.

Common fault analysis and solutions

Common faults of Perkins engine parts may be caused by many reasons. The following is the analysis and solutions of some common faults:

- The engine cannot start: Possible reasons include fuel supply problems (such as fuel pump failure, clogged fuel filter), ignition system problems (such as spark plug failure, ignition circuit failure) or battery problems (such as low battery power or poor wire contact) . Solutions include checking and replacing problematic accessories, cleaning or replacing the fuel filter, and ensuring the battery is adequately charged.

- The engine loses power or stops suddenly: Possible reasons include insufficient fuel supply (such as fuel pump failure, blocked fuel pipe), cooling problems (such as insufficient coolant, blocked radiator) or ignition system problems. Solutions include ensuring the fuel supply is functioning properly, checking coolant levels and cleaning the radiator, and checking that the ignition system is functioning properly.

- The engine produces abnormal noise: Possible causes include wear or damage caused by piston rings, oil pumps, crankshaft bearings or valves. Solutions include inspecting and replacing worn parts, ensuring proper fluid flow, and regular oil and filter changes.

- Black or white smoke from the engine: Black smoke can be a sign of burning too much fuel, which can be caused by a faulty fuel injector or a clogged air filter. White smoke may be a sign of water vapor entering the combustion chamber, possibly caused by coolant entering the combustion chamber. Solutions include checking and cleaning fuel injectors, replacing the air filter, and checking and repairing water leaks in the coolant system.

- Engine overheating: Possible causes include insufficient coolant, water pump failure, clogged radiator, or fan system failure. Solutions include ensuring coolant levels are adequate, checking and repairing water pump failures, cleaning the radiator, and ensuring the fan system is working properly.

Please note that this is just an analysis and solution example of some common faults. Specific problems may require further diagnosis and repair based on actual conditions. If you encounter a complex failure situation, it is recommended to seek professional Perkins engine repair and maintenance support.

YEM Professional Excavator Parts Team is a dedicated and experienced team that specializes in providing high quality parts for excavators. With extensive knowledge and expertise in this field, we are able to provide a wide range of parts to meet the diverse needs of our customers.

Whether you need replacement parts for hydraulic systems, engine components, chassis components or any other excavator component, the YEM team has you covered. We source our products from reputable manufacturers and ensure that each part meets the highest standards of quality and durability.

In addition to their impressive product selection, the YEM team prides itself on providing exceptional customer service. We understand the importance of timely support and strive to respond to inquiries and requests in a timely manner. Our knowledgeable staff is on hand to help customers identify the correct parts for their particular excavator model and provide installation and maintenance instructions.

To get in touch with the YEM Specialized Excavator Parts team you can contact us via our website, email or phone. We are committed to building long-term relationships with our customers and are eager to assist you with all your excavator parts needs.