What is the engine computer version? What it does and how it works

The Engine Control Unit (ECU) is a vehicle’s main electronic control device, used to manage and control various operations and functions of the engine. Its role is to monitor the operating status of the engine, receive and process sensor data, and make real-time adjustments based on these data to achieve optimal engine performance and fuel efficiency.

The engine computer works by interacting with multiple sensors and actuators. Sensors are responsible for monitoring various parameters of the engine, such as gas concentration, temperature, pressure, and rotational speed. These sensors transmit the collected data to the engine computer. The engine computer version makes corresponding adjustments and controls through actuators (such as injectors, throttles, ignition coils, etc.) based on real-time changes in sensor data to ensure the best operating status of the engine under various working conditions.

The working principle of the computer version of the engine is based on preset programs and algorithms. It contains a processor chip inside that can perform real-time calculations and processing according to program logic. By interacting with sensors and actuators, the engine computer version can automatically adjust and optimize the engine’s fuel injection, air-fuel ratio, ignition timing and other parameters based on current working conditions and driving needs to provide the best engine performance and fuel economy. .

All in all, engine computers play a vital role in modern cars, providing higher performance, better fuel economy and lower emission levels by monitoring and adjusting the engine’s operation in real time. It enables the engine to adapt to different working conditions and driving requirements, providing a better driving experience and reliability.

The main components of the engine computer version

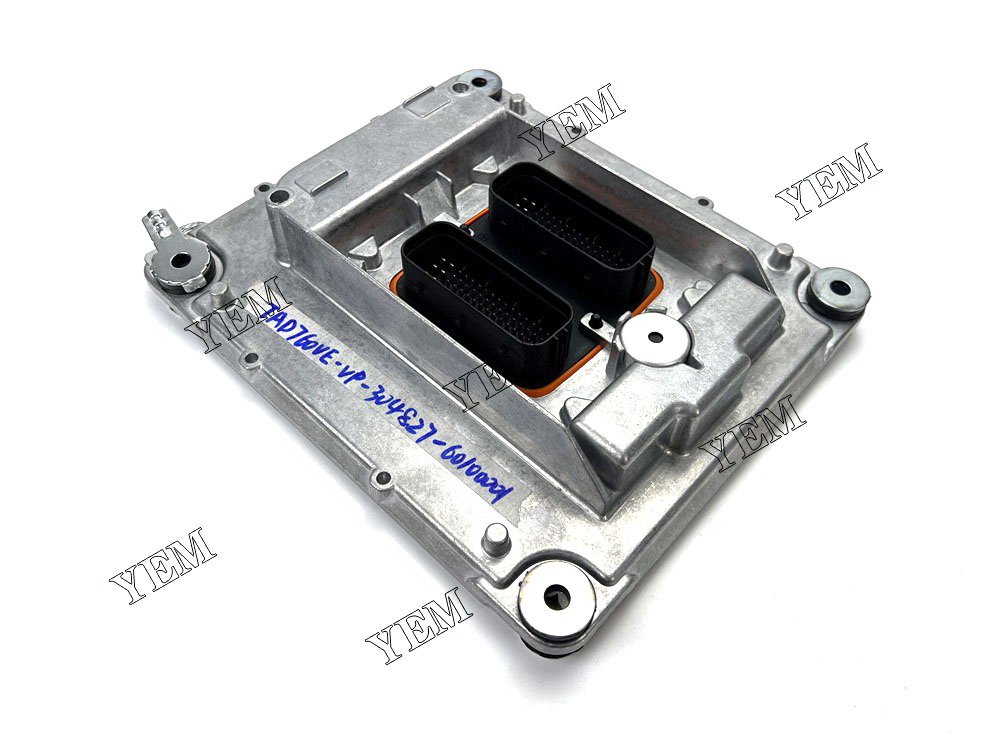

The Engine Control Unit (ECU) is a complex system composed of multiple components. The following are the main components of the engine computer version:

- Central processing unit (CPU): The central processing unit is the core of the engine computer and is responsible for processing and executing the calculations and instructions required for engine operation. The CPU is usually a high-performance microprocessor capable of quickly processing sensor data and controlling actuators.

- Memory: Memory is used to store the program code, data and temporary variables of the engine computer version. It includes two types of memory: read-only memory (ROM) and random-access memory (RAM). ROM stores fixed system programs and calibration data, while RAM stores real-time sensor data and calculation results.

- Input/output (I/O) interface: The I/O interface is used to connect the engine computer version to the engine’s sensors and actuators. It allows sensors to send real-time data of engine parameters to the ECU and allows the ECU to control actuators to adjust engine operation.

- Sensors: The engine computer version communicates with multiple sensors to monitor various parameters and working status of the engine. These sensors include oxygen sensors, temperature sensors, pressure sensors, speed sensors, etc., which provide real-time data information to the ECU.

- Actuator: The engine computer version controls and adjusts the operation of the engine through actuators. Actuators include fuel injectors, ignition coils, throttle actuators, etc. They receive instructions from the ECU and actually operate the engine as needed.

- Communication interface: The engine computer version is usually equipped with some communication interfaces to communicate with other vehicle systems, such as on-board diagnostic interface (OBD) or other remote monitoring systems.

The above are the main components of the engine computer. They cooperate with each other to enable the engine computer to monitor and control the working status of the engine and make real-time adjustments and optimizations as needed. Together, these components ensure the engine delivers optimal performance, fuel economy and emissions control under varying operating conditions.

Engine computerized version of sensors and actuators

The Engine Control Unit (ECU) controls the operation of the engine by interacting with multiple sensors and actuators. The following are some common types of sensors and actuators for engine computers:

Sensor:

- Oxygen sensor: used to measure the oxygen concentration in the exhaust gas to ensure that the engine is at the optimal air-fuel ratio.

- Temperature sensor: used to measure coolant and intake air temperature to help the ECU control ignition timing and fuel injection amount.

- Pressure sensor: used to measure intake air pressure and oil pressure to help the ECU adjust the fuel injection amount and air-fuel ratio.

- Throttle position sensor: used to measure the throttle opening to help the ECU control the air-fuel ratio and engine load.

- Speed sensor: used to measure the crankshaft speed to help the ECU determine the working status of the engine.

Actuator:

- Fuel injector: used to inject fuel into the cylinder for combustion and power generation.

- Transmission controller: used to control the operation of the automatic transmission to ensure smooth transition of engine operation and transmission under various working conditions.

- Ignition coil: used to generate high voltage, convert electrical signals into sparks, and ignite fuel to burn to generate energy.

- Throttle valve actuator: used to control the opening of the throttle valve to help the ECU control the air-fuel ratio and engine load.

The above are some common sensor and actuator types. Different car models and engine types may use different types and numbers of sensors and actuators, but they are all necessary components for ECU control and monitoring to send and receive data to ensure that the engine

Data input and output of engine computer version

The Engine Control Unit (ECU) communicates with other systems through data input and output. The following are some common data input and output methods:

Data input:

- Sensor data: The engine computer version reads real-time engine parameter data from the sensors by connecting to various sensors, such as oxygen sensor concentration, temperature sensor data, pressure sensor data, etc. This sensor data provides the ECU with real-time information on engine operating conditions.

- User input: The engine computer version can also receive input from the driver or vehicle operator, such as accelerator pedal position, brake pedal status, steering angle, etc. These user inputs can influence the ECU’s calculations and the engine’s control strategy to meet the driver’s needs.

Data output:

- Actuator control: The ECU adjusts and controls the operation of the engine by controlling various actuators, such as fuel injectors, ignition coils, throttle actuators, etc. Based on the analysis and logical calculation of sensor data, the ECU sends instructions to the actuator to control parameters such as fuel injection, ignition timing, air-fuel ratio, etc., to achieve ideal engine working conditions.

- Diagnostic data: The engine computer version can also output diagnostic data through the on-board diagnostic interface (OBD). These data include engine fault codes, sensor status, actuator status, etc., which can be read and analyzed through the OBD interface to help technicians perform fault diagnosis and repair.

- Instrument panel display: Some output signals of the ECU may be transmitted to the vehicle’s instrument panel for the driver to view and monitor engine status, such as engine temperature, fuel level, engine warning lights, etc.

These data input and output methods allow the engine computer to monitor and control engine operation in real time and communicate with other systems to achieve optimal engine performance, fuel economy and emissions control.

Troubleshooting and maintenance of engine computer version

Troubleshooting and maintenance are important links to ensure the normal operation of the Engine Control Unit (ECU) and optimal engine performance. Here are some common troubleshooting and maintenance steps:

- Diagnostic scan: If the engine has problems such as the malfunction indicator light coming on or poor performance, you can use the vehicle’s diagnostic tool or scanner to read the fault code in the ECU. The fault code will indicate the type and location of the possible fault and help locate the problem.

- Clear the fault code: Once the fault problem is confirmed and solved, the fault code in the ECU can be cleared through a diagnostic tool or scanner. Generally, after troubleshooting, the ECU will automatically erase some temporary fault codes, but some fault codes need to be cleared manually.

- Check sensor and actuator connections: Check whether the sensor and actuator connections are secure and properly connected. Loose or incorrect connections may cause sensor signal errors, affecting the ECU’s data reading and processing.

- Power supply check: Make sure the ECU power supply is stable and normal. Check the ECU’s power lines, fuses and relays to make sure they are in good working order.

- Software updates: Regularly check the engine computer version for software updates and upgrade the ECU firmware. Software updates and firmware upgrades can fix certain known issues and provide better performance and compatibility.

- Clean the air filter: Keep the air filter clean and unobstructed, which helps keep the engine computer getting accurate intake air data to support precise control of engine operation.

- Check the wiring harness and cable connections: Check the wires and connecting cables for damage, fraying or breaks, and make sure the connectors are making good contact. Damaged wiring harnesses and connections can cause circuit failures or signal interference.

Please note that for complex problems and repairs, it is recommended to seek professional technical support and repair. A skilled automotive technician or experienced repairman can better diagnose and resolve engine computer-related faults.

The future development of engine computer version

With the development of automobile technology and the improvement of electronics, the future development of engine computer version (Engine Control Unit, ECU) will have the following trends:

- More precise engine control: Future ECUs will not only monitor and control traditional parameters, such as engine temperature, accelerator pedal position, oxygen sensor data, etc., but will also monitor more parameters in real time, such as engine vibration, mass flow, etc. . These precise data will help the ECU control engine operation more accurately, thereby improving performance, reliability and fuel efficiency.

- Smarter decision-making: With the development of artificial intelligence and machine learning technology, future ECUs will have more advanced algorithms and self-learning functions, allowing them to make smarter decisions. For example, future ECUs may automatically adjust engine operation and driving modes based on the driver’s driving behavior and road conditions to maximize vehicle performance and fuel economy.

- Wireless communication: Future ECUs will have wireless communication technology and can communicate with other vehicles, traffic lights, roadside sensors, etc. to achieve smarter traffic flow control and enhance driving safety.

- Multi-mode: Future ECUs will be able to support multiple driving modes, such as snow, off-road, track and other modes. The driver can adjust engine operation to suit different road and driving conditions by switching modes.

In short, future engine computer versions will be more intelligent and precise, and will achieve higher levels of autonomous driving and intelligent transportation through integration with other systems. These advances will improve the sustainability of the automotive industry

Contact us

Thank you for reaching out to our YEM team. We take great pride in providing exceptional service and support to our valued customers. If you have any questions or need assistance, please don’t hesitate to reach out to us through any of the following channels:

Rest assured, we are here to assist you and are eager to resolve any inquiries you may have.