Engine air compressor mechanism and working principle

The engine air compressor is a device used to supply compressed air to the engine. Its mechanism and working principle are as follows:

- Air intake: The engine air compressor inhales air from the surrounding environment and introduces it into the air filter for preliminary filtration to remove impurities and particulate matter.

- Compressed air: The preliminarily filtered air enters the compressor, and the compressor compresses the air to the required high-pressure state through rotating rotors, pistons or centrifugal force. Different types of engine air compressors use different compressor designs, such as centrifugal, screw or piston compressors.

- Cooling: Since the compression process of air generates heat, the engine air compressor usually needs to be cooled to reduce the temperature. The cooling system can be air-cooled or liquid-cooled to ensure the air is at the right temperature before entering the engine.

- Gas storage: After the compressed air is cooled, it will enter the gas tank or gas storage system to provide a stable high-pressure air supply when the engine needs it.

- Air supply: The engine is connected to the gas tank or gas storage system through pipelines, and high-pressure air is supplied to the combustion chamber of the engine or other equipment that requires aerodynamics. These devices may include ignition systems, fuel injection systems, turbochargers, etc. to support the combustion process and provide additional power.

Through this series of steps, the engine air compressor realizes the function of compressing air from the surrounding environment and providing it to the engine. This high-pressure air plays an important role during engine operation, ensuring that the engine operates properly and provides the required power output.

Different types of engine air compressors

There are several different types of engine air compressors used in various applications. Some common types include:

1. Reciprocating Compressors: Also known as piston compressors, these compressors use a reciprocating motion of a piston within a cylinder to compress the air. They are commonly used in small to medium-sized engines and have a relatively simple construction.

2. Rotary Screw Compressors: These compressors use two rotating screws to compress the air. As the screws rotate, the air is trapped and compressed in the spaces between them. Rotary screw compressors are widely used in industrial engines and high-demand applications.

3. Centrifugal Compressors: Centrifugal compressors use centrifugal force to accelerate and compress the air. The air is guided into a rapidly rotating impeller, which imparts kinetic energy to the air, and then it is converted into pressure by a diffuser. These compressors are commonly used in large engines and power plants.

4. Axial Compressors: Axial compressors use a series of rotating blades to compress the air. As the air flows through the compressor, the blades compress it by increasing its velocity. Axial compressors are commonly used in aircraft engines and gas turbines.

5. Scroll Compressors: Scroll compressors use a pair of spiraled scrolls to compress the air. One scroll remains stationary, while the other orbits around it, trapping and compressing the air between them. They are commonly used in automotive air conditioning systems and small engines. These are just a few examples of the different types of engine air compressors available. The selection of a compressor type depends on factors such as the application, desired air pressure, flow rate, and efficiency requirements.

Composition and functions of air compressor system

The air compressor system consists of various components that work together to compress and supply compressed air. Here are the key components and their functions:

1. Compressor: The compressor is the main component responsible for compressing atmospheric air. It takes in air and reduces its volume to increase its pressure. The type of compressor can vary, such as reciprocating, rotary screw, centrifugal, etc., depending on the application.

2. Motor or Engine: The motor or engine provides the power to drive the compressor. It can be an electric motor or an internal combustion engine, depending on the system requirements.

3. Air Intake System: The air intake system ensures a continuous flow of ambient air into the compressor. It usually includes filters to remove dust, debris, and contaminants from the incoming air to protect the compressor and downstream components.

4. Cooling System: Compressing air generates heat, and a cooling system is employed to dissipate the heat and maintain the temperature within acceptable limits. It can include air or water cooling methods, such as radiators, fans, heat exchangers, or intercoolers.

5. Compressed Air Receiver or Tank: The compressed air receiver or tank stores the compressed air and provides a reservoir for immediate use. It helps regulate pressure fluctuations and allows for a steady supply of compressed air during peak demands.

6. Pressure Regulation System: The pressure regulation system consists of pressure switches, regulators, and control valves. These components help monitor and control the pressure levels within the system, ensuring that it stays within the desired range for safe and efficient operation.

7. Air Treatment Components: Depending on the application, additional components may be included to treat the compressed air. These can include filters to remove moisture, oil, and particulate matter, as well as dryers, separators, and condensate drains.

8. Distribution System: The distribution system consists of pipes, hoses, valves, and fittings that transport the compressed air from the receiver to the points of use. It is designed to minimize pressure losses and optimize the efficiency of air delivery.

9. Safety Devices: Safety devices like relief valves, check valves, and gauges are installed to ensure the proper functioning and safety of the air compressor system. They protect against overpressure, prevent backflow, and provide pressure and temperature readings for monitoring.

10. Control System: The control system includes a control panel or interface that allows operators to monitor and control various parameters of the air compressor system. It may include displays, buttons, switches, and programmable logic controllers (PLCs) for automation and system management. These components work in harmony to supply compressed air for various applications, such as powering pneumatic equipment, operating machinery, supplying clean air for breathing apparatus, and more.

Air compressor maintenance and troubleshooting

Proper maintenance and timely troubleshooting are essential to ensure the efficient operation of an air compressor. Here are some tips to help you with air compressor maintenance and troubleshooting:

- Regularly check and change the oil: Refer to the manufacturer’s guidelines for the recommended oil type and interval for oil changes. Dirty or insufficient oil can lead to reduced performance and potential damage.

- Clean or replace the air filters: Clogged air filters restrict airflow and can result in decreased efficiency. Clean or replace the air filters as recommended by the manufacturer.

- Drain moisture from the tank: Condensation can accumulate inside the air compressor tank, leading to corrosion and reduced performance. Drain the moisture regularly to prevent any damage.

- Inspect and tighten connections: Check for any loose connections, including air hoses, fittings, and bolts. Tighten them as needed to prevent air leaks and maintain optimal performance.

- Monitor and adjust pressure settings: Regularly check the pressure settings of your air compressor to ensure they are within the recommended range. Incorrect pressure settings can lead to inefficient operation and potential damage.

- Address strange noises or vibrations: Unusual noises or excessive vibrations can indicate underlying issues. Investigate and address these problems promptly to prevent further damage.

- Ensure proper ventilation: Place the air compressor in a well-ventilated area to prevent overheating. Poor ventilation can affect performance and potentially lead to malfunctions.

If you encounter persistent issues or are unsure about any maintenance or troubleshooting steps, it’s best to consult the manufacturer’s documentation or seek professional assistance from a qualified technician.

Engine air compressor application areas and key industries

Engine air compressors find applications in various industries where compressed air is essential for powering equipment and machinery. Some of the key industries that heavily rely on engine air compressors include:

- Manufacturing and Industrial: Engine air compressors are widely used in manufacturing and industrial settings for a range of applications such as operating pneumatic tools (e.g., drills, grinders, sanders), powering conveyor systems, providing compressed air for paint spraying, controlling robotic systems, and operating assembly line equipment.

- Construction and Infrastructure: Engine air compressors play a critical role in construction projects, powering pneumatic tools like jackhammers, concrete breakers, nail guns, and spray guns for painting. They are also used to operate pneumatic controls for heavy machinery, including cranes and excavation equipment.

- Automotive and Transportation: In the automotive industry, engine air compressors are used for various applications including tire inflation, powering pneumatic tools for repair and maintenance, operating spray booths for painting, and providing compressed air for vehicle pneumatic systems.

- Oil and Gas: Engine air compressors are used in the oil and gas industry for various purposes such as powering drilling equipment, driving pneumatic controls and actuators in pipeline systems, and providing compressed air for pneumatic conveying and pressurized storage.

- Food and Beverage: Engine air compressors find applications in the food and beverage industry for processes such as packaging, bottling, air cleaning, and pneumatic conveying. They are also used for aeration in wastewater treatment plants.

- Pharmaceutical and Medical: In the pharmaceutical and medical sectors, engine air compressors are utilized for applications like powering pneumatic control systems, operating medical devices, and providing compressed air for cleanrooms.

- Energy and Utilities: Engine air compressors are used in power plants, both conventional and renewable, for various purposes such as providing compressed air for combustion control systems, pneumatic conveying of coal or biomass, and operating pneumatic controls in various equipment.

These application areas demonstrate the versatility and importance of engine air compressors across a wide range of industries, highlighting their role in powering crucial operations and enabling various processes.

Contact us

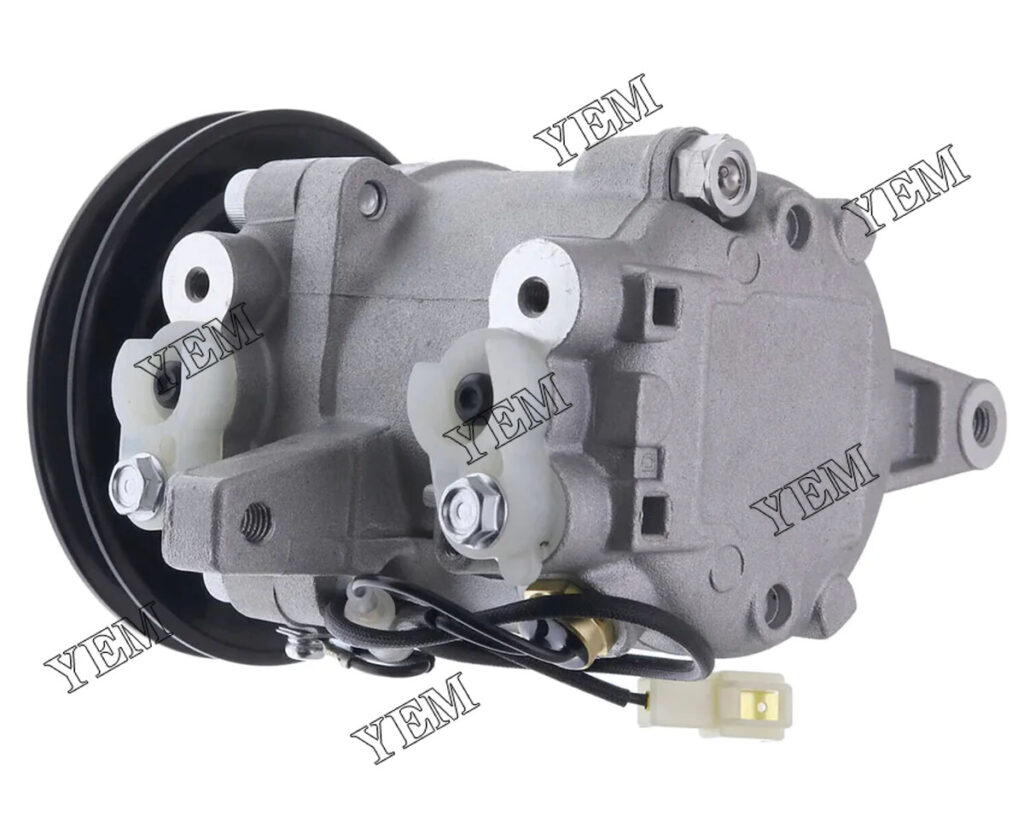

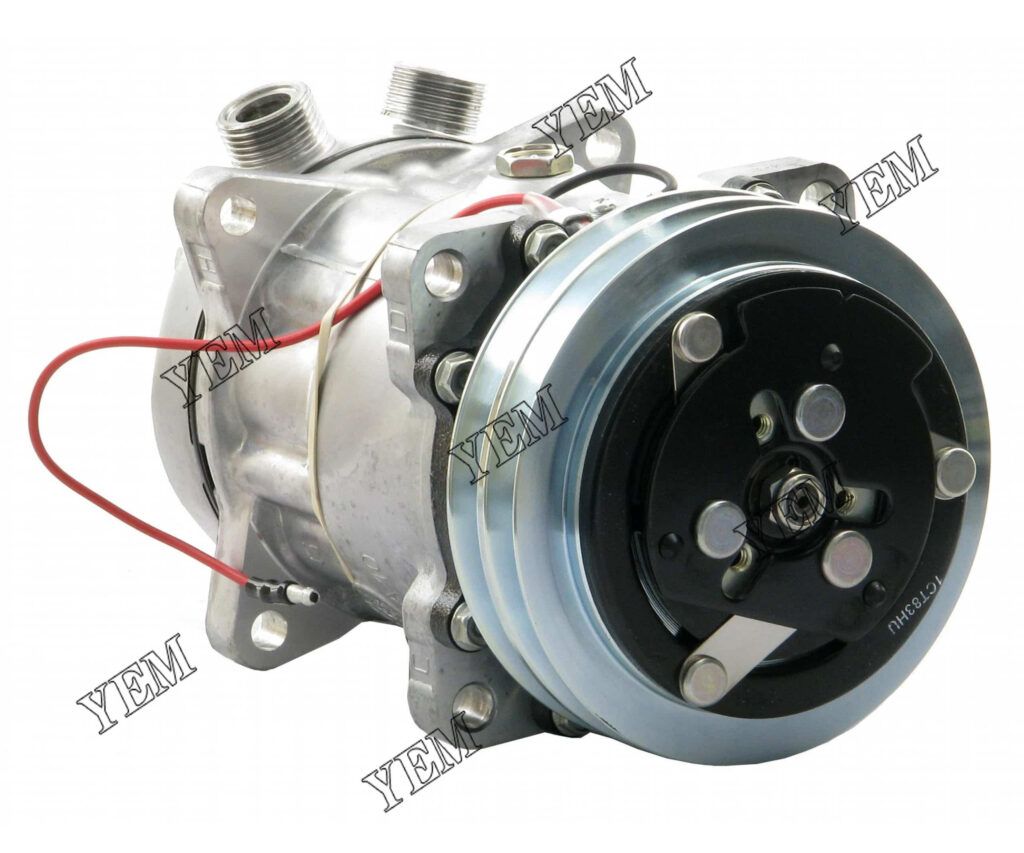

YEM Excavator Parts Team is a dedicated and experienced team that specializes in quality parts for excavators. With our extensive knowledge and expertise in this industry, we offer a wide range of parts to meet the needs of different customers.

Our products cover all kinds of excavator parts, including hydraulic system, engine parts, chassis parts and so on. We take pride in sourcing our parts from reliable manufacturers, ensuring that each component meets the highest standards of quality and durability.

What sets us apart is our unwavering commitment to exceptional customer service. We understand the importance of timely support and our team is always available to respond to inquiries and requests in a timely manner. Our knowledgeable staff is on hand to help customers identify the correct parts for their particular excavator model and provide detailed installation and maintenance instructions.

To get in touch with our dedicated excavator parts team, feel free to contact us via our website, email or phone. We are committed to building long-term relationships with our customers and eagerly look forward to assisting you with all of your excavator parts needs.