Excavator hydraulic pump basics

The hydraulic pump is one of the essential components in an excavator’s hydraulic system. Here are the basics of the excavator hydraulic pump:

- Function: The hydraulic pump is responsible for generating hydraulic pressure and supplying hydraulic fluid to drive the various hydraulic actuators in the excavator, such as the boom, arm, and bucket cylinders. It converts mechanical power, typically provided by the engine, into hydraulic power.

- Types of Hydraulic Pumps: There are mainly two types of hydraulic pumps used in excavators: gear pumps and piston pumps.

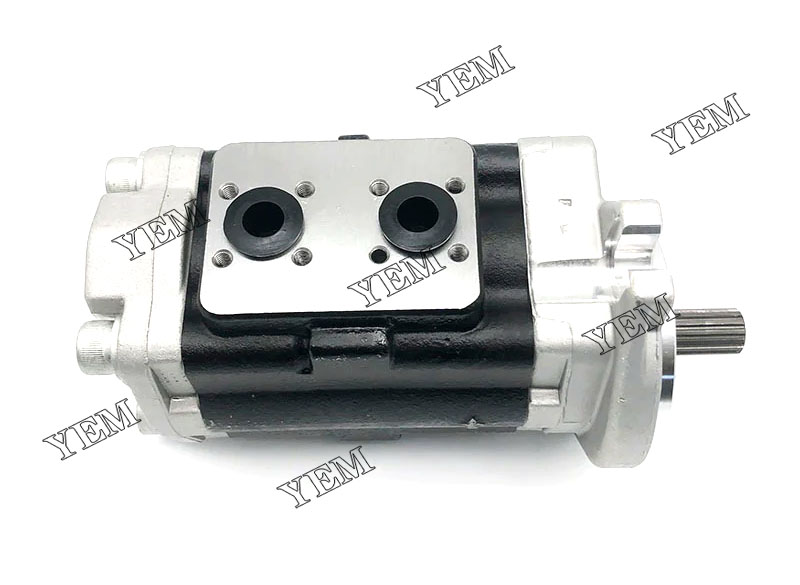

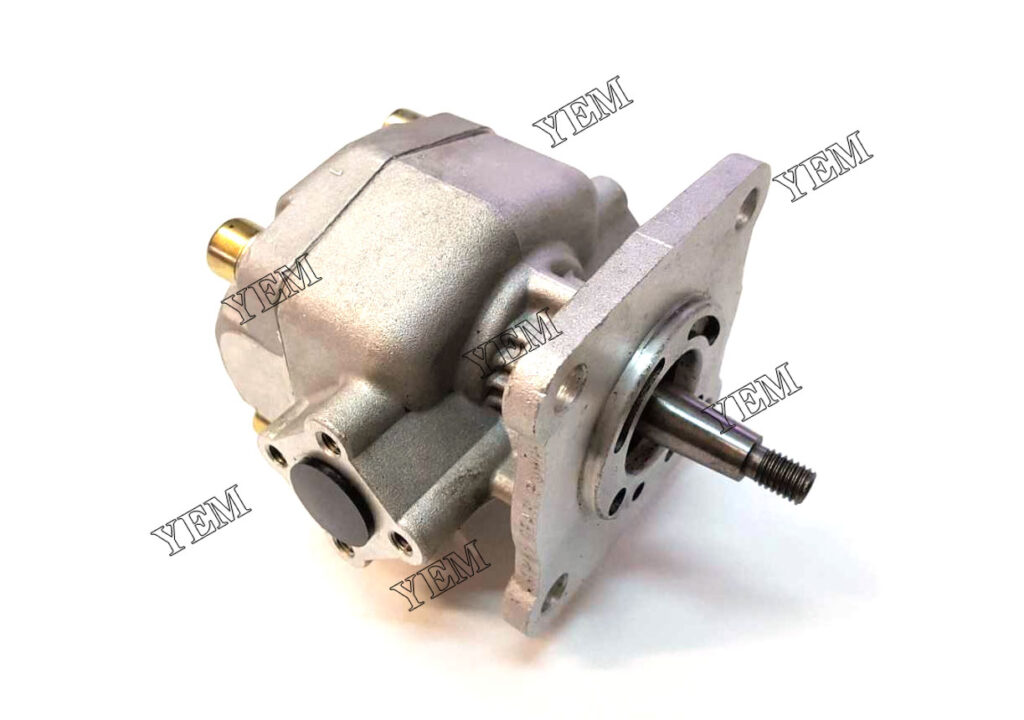

- Gear pumps: Gear pumps are commonly used in smaller excavators. They consist of two meshed gears that create suction and pressure as they rotate, resulting in the flow of hydraulic fluid.

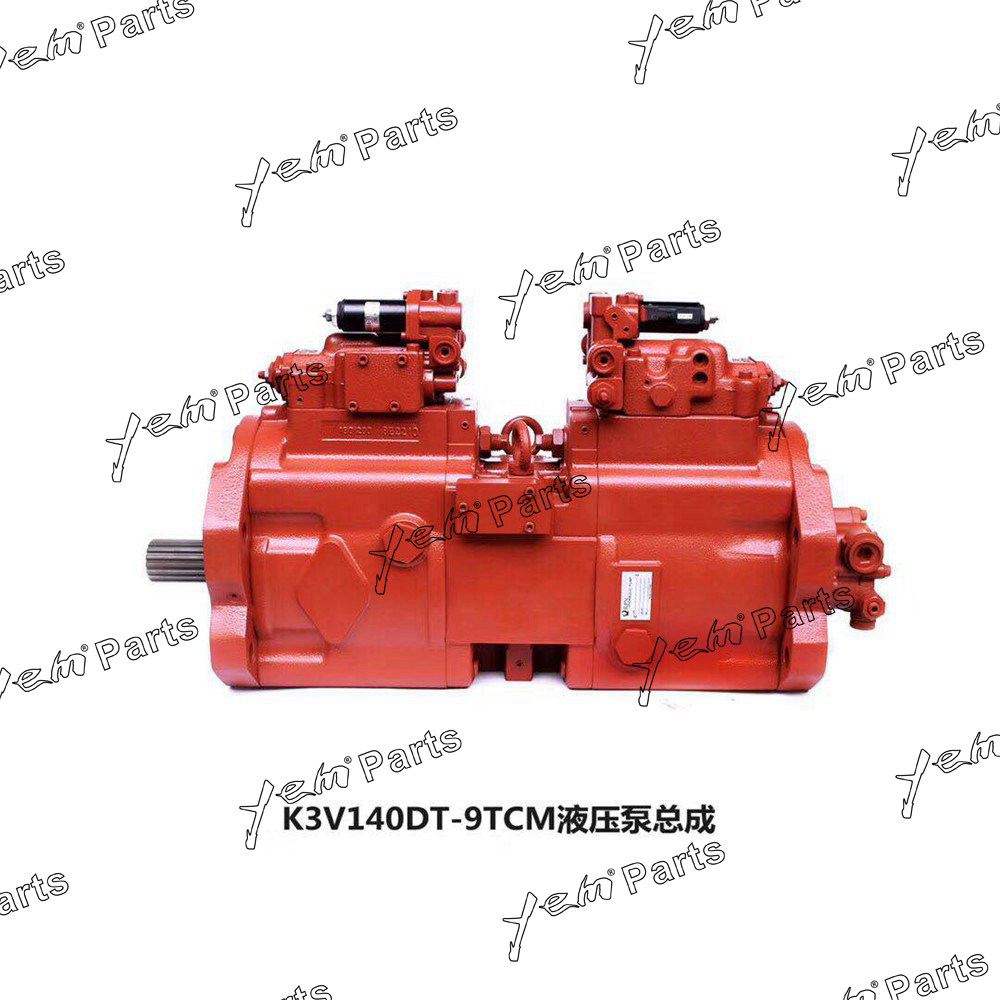

- Piston pumps: Piston pumps are typically used in larger excavators. They use reciprocating pistons to pressurize the hydraulic fluid. There are two common types of piston pumps: axial piston pumps and radial piston pumps.

- Operating Principle: The hydraulic pump operates based on the positive displacement principle. It means that a fixed amount of hydraulic fluid is moved per revolution or stroke of the pump. As the pump rotates or reciprocates, it creates a low-pressure suction side and a high-pressure discharge side to generate hydraulic power.

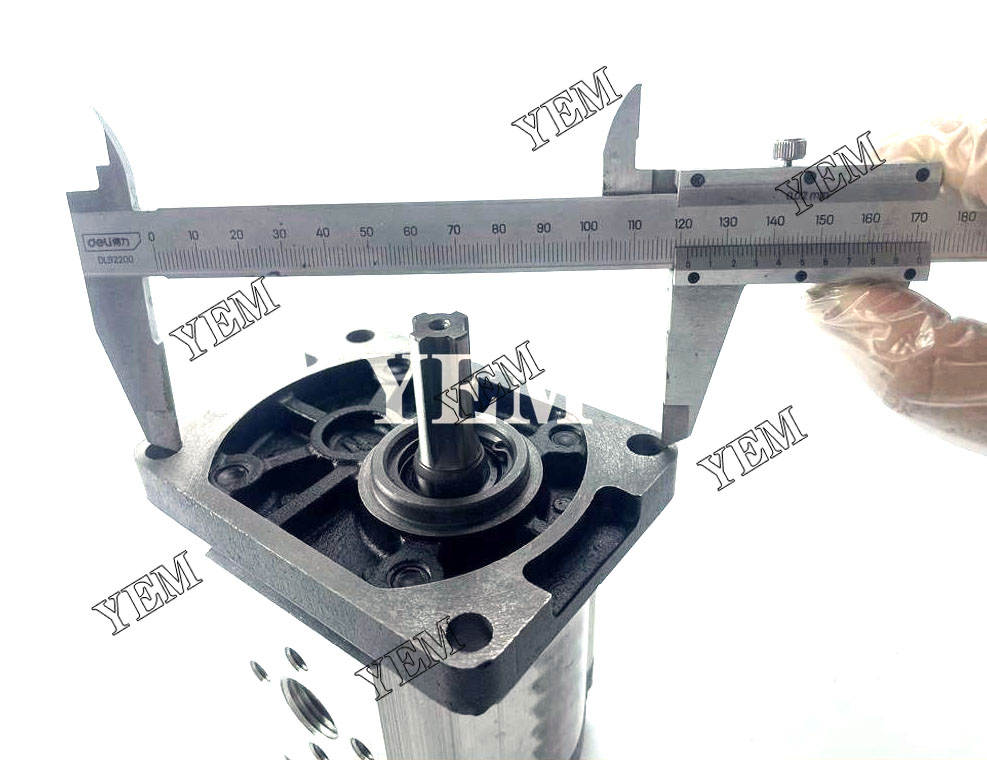

- Flow and Pressure: Hydraulic pumps are rated for their flow rate and pressure capability. The flow rate is typically measured in liters per minute (L/min) or gallons per minute (GPM), representing the volume of hydraulic fluid the pump can deliver. The pressure rating is measured in pounds per square inch (PSI) or bars, indicating the maximum pressure the pump can generate.

- Maintenance and Troubleshooting: Proper maintenance of the hydraulic pump is crucial to ensure its efficient operation. Regular inspection, lubrication, and fluid condition checks are essential. If the pump fails, it can be due to various reasons such as worn-out seals, contamination, or internal component failure. Troubleshooting should involve inspecting the pump, associated valves, and the hydraulic system as a whole.

These are the fundamental aspects of excavator hydraulic pumps. Understanding these basics can help operators and maintenance personnel in their work with hydraulic systems and troubleshooting any related issues.

Excavator Hydraulic Pump Troubleshooting

When troubleshooting an excavator hydraulic pump, it’s important to consider several potential causes for issues. Here are some common troubleshooting steps for excavator hydraulic pump problems:

- Insufficient/No Hydraulic Pressure:

- Check the hydraulic fluid level and ensure it’s at the recommended level.

- Inspect the hydraulic filters for clogs or signs of contamination and replace them if necessary.

- Check for leaks in the hydraulic system, including hoses, fittings, and connections.

- Inspect the hydraulic pump for any signs of damage or wear and replace it if needed.

- Verify that the hydraulic pump is receiving adequate power from the engine or auxiliary power source.

- Overheating:

- Check the hydraulic fluid temperature using a thermometer or temperature gauge. Ensure it’s within the recommended operating range.

- Inspect the hydraulic cooler for any blockages or debris and clean it if necessary.

- Verify that the hydraulic pump is appropriately sized for the hydraulic system’s requirements.

- Ensure that the hydraulic system’s flow control valves are correctly set to prevent excessive heat buildup.

- Unusual Noises or Vibrations:

- Inspect the hydraulic pump and associated components for loose or worn-out parts and tighten or replace them as needed.

- Check for cavitation, which occurs when the pump’s suction side experiences low hydraulic fluid levels or air entrapment. Address any issues causing cavitation, such as leaks or inadequate fluid levels.

- Verify that all mounting bolts and brackets for the pump are securely fastened.

- Check the condition of the hydraulic fluid and replace it if it’s contaminated or degraded.

- Loss of Power or Performance:

- Inspect the hydraulic pump for any worn-out or damaged internal components, such as pistons, valves, or seals, and replace them if necessary.

- Check the hydraulic lines and connections for leaks or restrictions that may be affecting the fluid flow.

- Inspect other hydraulic system components, such as control valves and actuators, for any issues that could be impacting overall performance.

- Ensure that the hydraulic pump‘s rotation speed and flow rate are within the manufacturer’s recommended specifications.

If these troubleshooting steps don’t resolve the issue, it may be necessary to consult the excavator’s service manual or contact a qualified technician for further assistance.

Hydraulic Pump Maintenance Guide

Proper maintenance of a hydraulic pump is essential for ensuring its longevity and performance. Here is a guide to help you with hydraulic pump maintenance:

- Regular Inspections:

- Perform visual inspections of the pump and associated components to check for any signs of wear, leaks, or damage. Address any issues immediately.

- Inspect hydraulic hoses, fittings, and connections for leaks, cracks, or deteriorated seals. Replace any damaged or worn-out parts.

- Check the hydraulic fluid level and condition regularly. Top up or replace the fluid as needed, following the manufacturer’s recommendations.

- Fluid Maintenance:

- Use the recommended hydraulic fluid specified by the pump manufacturer. Ensure the fluid meets the required viscosity and additives for optimal performance.

- Regularly test the hydraulic fluid for contaminants, such as water, dirt, or metal particles. Utilize proper filtration systems to maintain clean fluid.

- Maintain the appropriate fluid level at all times, avoiding both overfilling and operating with low fluid levels.

- Follow the recommended fluid change intervals provided by the pump manufacturer.

- Filter Maintenance:

- Regularly inspect and replace the hydraulic filters as per the manufacturer’s recommendations. Dirty or clogged filters can cause pump damage and reduce efficiency.

- Ensure the filter housing is properly sealed to prevent contaminants from bypassing the filtration system.

- Clean or replace suction strainers to prevent clogging and ensure an uninterrupted fluid supply to the pump.

- Temperature Control:

- Monitor the operating temperature of the hydraulic pump using temperature gauges or sensors. Ensure it remains within the manufacturer’s specified range.

- Regularly clean or replace hydraulic coolers, radiators, or fans to prevent overheating. Ensure proper airflow for effective cooling.

- Lubrication:

- Apply appropriate lubrication as per the manufacturer’s recommendations to bearings, gears, and other moving parts.

- Regularly check and adjust belt tension, if applicable, to ensure effective power transfer from the motor to the pump.

- Correct Usage:

- Operate the hydraulic pump within its specified parameters, avoiding excessive loads, pressure spikes, or continuous high-speed operation.

- Educate and train operators on proper pump usage and maintenance to prevent inadvertent damage.

- Professional Servicing:

- Schedule periodic maintenance and inspections by qualified technicians to identify potential issues early and perform more in-depth servicing.

Remember to always refer to the specific maintenance guidelines provided by the hydraulic pump manufacturer. Adhering to regular maintenance practices will help extend the lifespan of the pump and maintain optimal performance.

Types and selection of excavator hydraulic pumps

Excavator hydraulic pumps can be categorized into three main types: gear pumps, piston pumps, and vane pumps.

- Gear Pumps: Gear pumps are the most common type of hydraulic pump used in excavators. They consist of two meshing gears that create a vacuum which draws in hydraulic fluid. As the gears rotate, the fluid is squeezed and forced out through the pump’s outlet. Gear pumps are relatively simple, compact, and cost-effective, making them suitable for lower-pressure applications.

- Piston Pumps: Piston pumps are capable of generating higher pressures than gear pumps, making them suitable for heavy-duty excavator applications. They feature pistons that reciprocate within a cylinder block to generate hydraulic flow. Piston pumps can be further classified into axial piston pumps and radial piston pumps. Axial piston pumps are more commonly used in excavators due to their higher efficiency and compact design.

- Vane Pumps: Vane pumps utilize a rotor with vanes that slide in and out of slots to create hydraulic flow. They are known for their low noise levels, smooth operation, and relatively high efficiency. However, vane pumps may not be as durable as gear pumps or piston pumps in harsh operating conditions.

The selection of an excavator hydraulic pump depends on various factors, including the excavator’s size, operating pressure requirements, flow rate needs, and the specific application. Considerations such as the required power, efficiency, and reliability should also be taken into account. It is crucial to consult with hydraulic pump manufacturers or experts to ensure the optimal selection of a hydraulic pump for your excavator.

Excavator hydraulic system optimization

Optimizing an excavator’s hydraulic system can greatly enhance its performance, efficiency, and overall productivity. Here are some key considerations for excavator hydraulic system optimization:

- Proper Hydraulic Fluid: Ensure that the excavator is using the correct type and grade of hydraulic fluid recommended by the manufacturer. Regularly monitor and maintain the fluid’s cleanliness to prevent contamination and maximize system efficiency.

- Efficient Pump Selection: Select a hydraulic pump that matches the excavator’s power and flow requirements, considering factors such as operating pressure, flow rate, and duty cycle. Choosing the most suitable pump type, such as piston pumps for higher pressures or gear pumps for standard applications, can optimize system performance.

- System Design: Optimize the hydraulic system design by minimizing pressure losses, using proper pipe sizing, and reducing unnecessary bends and fittings. This will help maintain efficient flow throughout the system and minimize energy losses.

- Hydraulic Valves: Properly sized and balanced hydraulic valves can optimize control and response of the excavator. Proportional and load-sensing valves can help regulate flow and pressure based on the specific requirements, improving energy efficiency.

- Filtration and Cooling: Utilize effective filtration systems to remove contaminants from the hydraulic fluid, preventing damage to components and maintaining system performance. Proper cooling systems, such as radiators or coolers, can also prevent overheating and ensure efficient operation.

- Regular Maintenance: Implement a proactive maintenance program to regularly inspect, clean, and replace hydraulic components as needed. This includes servicing filters, checking for leaks, maintaining proper fluid levels, and verifying system pressures.

- Operator Training: Provide operators with proper training on excavator operation and hydraulics, emphasizing efficient usage techniques and best practices. Skilled operators can optimize control and minimize unnecessary hydraulic actions, reducing energy consumption.

By considering these aspects and regularly evaluating the hydraulic system’s performance, excavator owners can achieve enhanced efficiency, longer component life, and improved productivity. Consulting with hydraulic system experts or manufacturers can further assist in optimizing the excavator’s hydraulic system.

Contact us

Our YEM team comprises a skilled and passionate group of engineers and technicians specializing in excavator parts. With years of experience in the industry, we are dedicated to delivering top-quality excavator accessories and comprehensive solutions tailored to meet our customers’ needs.

We pride ourselves on our profound understanding of excavators, their working principles, and the functionalities of accessories. This enables us to provide accurate and professional recommendations to our customers. In collaboration with renowned excavator parts manufacturers and suppliers, we ensure the products we offer are of exceptional quality and reliability.

Our expertise covers all types and brands of excavators. Whether it’s replacing a damaged excavator accessory or upgrading the excavator’s function and performance, our team can provide a comprehensive solution. We consider customers’ requirements and budget to provide the most suitable accessory options while ensuring smooth installation and maintenance processes.

Beyond supplying excavator accessories, our services encompass transportation, installation, repairs, and after-sales support. Customer satisfaction is our utmost priority, and we strive to deliver outstanding service and the best solutions.

Thank you for your interest in the YEM excavator parts team. Should you have any inquiries or requirements, please do not hesitate to contact us. We look forward to providing you with high-quality excavator accessories and professional technical support.