The function and principle of water pump

A pump is a device used to draw a liquid (usually water) from one place and pipe it to another. In the engine, the water pump is mainly used to circulate the coolant (coolant) to reduce the engine temperature and ensure the normal operation of the engine.

The working principle of the water pump is based on the principle of centrifugal force and volume expansion. A water pump usually consists of a drive shaft and an impeller. When the engine is running, the drive shaft turns, which turns the impeller. The blades inside the impeller will draw liquid into the pump through centrifugal force, and the rotation of the impeller will push the liquid into the pipe.

Specifically, the working process of the water pump is as follows:

The impeller of the water pump is driven by the crankshaft of the engine.

As the impeller rotates, the blades draw liquid from the water inlet of the pump through centrifugal force.

Liquid is pushed to the outlet of the water pump and piped into the cooling system.

The liquid in the cooling system absorbs the heat generated by the engine and reduces the engine temperature.

The coolant returns to the water pump again and the cycle continues.

In short, the water pump sucks and pushes the liquid from one place to another through the centrifugal force and the rotation of the impeller to realize the circulation and transportation of the liquid. In the engine, the role of the water pump is to circulate the coolant to ensure that the temperature of the engine is within the normal operating range

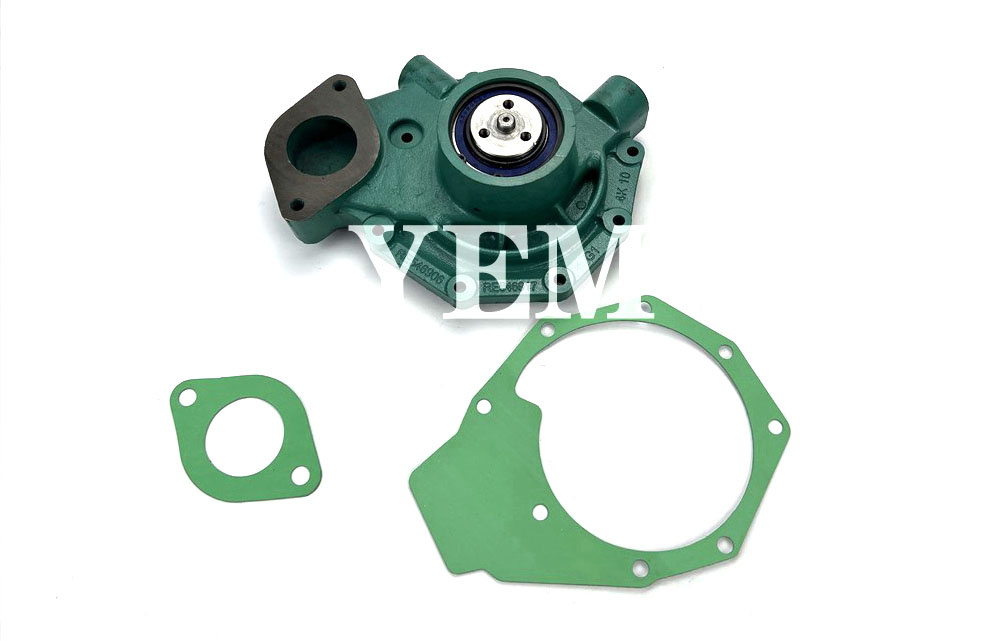

Structure and components of engine water pump

The structure and components of the engine water pump include the following main parts:

Water pump housing: The water pump housing is the external structure of the water pump, usually made of cast iron or aluminum alloy. It carries the other components of the pump and provides support and sealing.

Impeller: The impeller is the heart of the pump and is usually made of cast iron or plastic. It is a disc-shaped component with multiple blades inside. As the impeller spins, the blades use centrifugal force to draw liquid into and push it out of the pump.

Bearings: The bearings of the water pump are used to support and position the impeller and drive shaft. Common bearing types include rolling and plain bearings.

Seals: The seals of the water pump are used to prevent coolant leakage. Common seals include mechanical seals and seal rings. A mechanical seal is usually composed of a static ring, a moving ring and a sealing surface, which are kept in close contact by springs or other devices. A seal is a rubber or silicone ring that prevents fluid from leaking.

Drive: The drive for the water pump is usually the crankshaft of the engine. The crankshaft transmits power to the impeller of the water pump through a belt, chain or gear drive.

In addition to the above main components, the water pump may also include other auxiliary components, such as water inlet, water outlet, coolant temperature sensor, etc., to meet the needs of specific applications.

These constructions and components work together to allow the water pump to draw coolant and circulate it into the engine’s cooling system to maintain the engine’s normal operating temperature.

Water pump failure and repair

There are some common failures that water pumps can experience that require servicing and repairs accordingly. The following are some common water pump failures and corresponding repair methods:

Leaks: The water pump may leak, causing loss of coolant. Common causes of leakage include damaged or loose seals, cracked housings, etc. Repair methods include replacing the seal or repairing the housing.

Bearing wear: Prolonged use or improper use can cause water pump bearings to wear out. Worn bearings can cause the water pump to be noisy or run rough. Repair methods include replacing the bearings.

Impeller Corrosion: If the coolant contains corrosive substances or if an unsuitable coolant is used, the impeller may corrode. A corroded impeller will reduce the efficiency of the water pump. Repair methods include cleaning the impeller or replacing the impeller.

Drive failure: The pump drive, such as a belt, chain, or gear drive, may be loose, broken, or worn. Repair methods include adjusting or replacing the drive unit.

Blocked Water Inlet or Outlet: The water inlet or outlet can become clogged with debris or sediment, causing the pump to reduce flow or completely block it. Repair methods include clearing the blockage.

Water pump noise: The abnormal noise generated during the operation of the water pump may be caused by bearing wear, impeller imbalance, impurities entering and other reasons. Repair methods include replacing bearings, balancing the impeller, or cleaning up impurities

For pump repairs, it is recommended to seek the help of a professional technician, especially for complex repairs that involve disassembly and assembly of the pump. In addition, regular inspection and maintenance of the water pump is also an important measure to prevent failures, including cleaning the cooling system and replacing the coolant.

Water pump selection and installation

Selecting and installing a water pump is key to ensuring it runs properly and works efficiently. The following are key points to consider when selecting and installing a water pump:

Flow and head requirements: Select the appropriate water pump model and specification according to the coolant flow and head to be delivered. The flow rate refers to the amount of liquid that the pump can deliver per unit time, and the head refers to the vertical height that the liquid needs to overcome from the pump suction port to the water outlet.

Adapt to the environment and media: Consider the environmental conditions where the pump will be installed, such as temperature, humidity, corrosive media, etc. Choose materials and coatings that are resistant to environmental conditions and media to ensure long pump life.

Installation location and layout: Choose a suitable installation location and layout to ensure that the water pump can be easily connected to the cooling system and there is enough space for repair and maintenance.

Drive mode: Select the appropriate drive mode according to the needs, such as electric drive, hydraulic drive or engine drive, to ensure that the water pump can obtain enough power.

Installation method and steps: Follow the installation guidelines and instructions provided by the pump manufacturer to install the pump correctly. Make sure that the connection between the water pump and the cooling system is tight, well-sealed, and there are no leaks or looseness.

Coolant Fill and Bleed: After installation, make sure that the coolant in the cooling system is fully filled and the air is purged. This can be done by opening the cooling system’s exhaust valve or by turning on the cooling system’s circulation.

Tests and Adjustments: Before starting the pump, make the necessary tests and adjustments to make sure the pump is functioning properly and check for any leaks or unusual noises.

Regular maintenance and maintenance: regular inspection and maintenance of the water pump, including cleaning the cooling system, replacing the coolant, checking the seals, etc., to prolong the service life of the water pump and keep it in good working condition.

Please note that it is recommended to seek the help of a professional technician when installing the pump, especially for complex installation work involving plumbing connections and electrical wiring.

Water pump maintenance and upkeep

The regular maintenance and maintenance of the water pump is an important measure to ensure its normal operation and prolong its service life. Here are some common water pump maintenance and maintenance points:

Regular inspection: Regularly check the working status of the water pump, including observing whether there is water leakage, abnormal noise or vibration, etc. Check whether the driving device, connecting parts and seals of the water pump are tight, loose or worn.

Clean the cooling system: Regularly clean the cooling system to prevent sediment, dirt or impurities in the coolant from clogging the water pump or cooling system pipes. The cooling system can be cleaned with a suitable cleaning agent or by flushing with water.

Changing the coolant: Change the coolant regularly to maintain its cooling performance and anti-corrosion performance. Follow the pump manufacturer’s recommendations or the coolant manufacturer’s instructions to determine how often and how to change the coolant.

Check the seals: Regularly check the seals of the water pump, such as mechanical seals or sealing rings. Make sure the seals are not worn, aged or leaking. If necessary, replace seals to prevent fluid leakage.

Bearing Lubrication: Lubricate the bearings of the water pump regularly according to the pump manufacturer’s recommendations. Use an appropriate lubricant and ensure that the quality and quantity of lubricant meet the requirements.

Antifreeze measures: If the pump is located in an environment where it will be frequently exposed to low temperatures or freezing conditions, take appropriate antifreeze measures. This can include using antifreeze coolant or draining the cooling system when it’s cold.

Regular maintenance: According to the pump manufacturer’s recommendations, perform regular maintenance work, such as cleaning the impeller, calibrating the drive unit, checking the electrical wiring, etc.

Please note that the above are general water pump maintenance and maintenance points, specific maintenance measures may vary according to the type of water pump, usage and manufacturer’s recommendations. It is recommended to refer to the user manual of the water pump or consult a professional technician

Market and development trends of water pumps

A water pump is a mechanical device used to transport liquids and is widely used in construction, agriculture, industry, energy and other fields. The water pump market is affected by factors such as economic development, urbanization process, and environmental protection requirements, and presents the following market and development trends on a global scale:

- Expanding market size: With the development of the economy and the acceleration of urbanization, the demand for water pumps continues to increase. Especially in emerging markets and developing countries, driven by infrastructure construction and industrial capacity expansion, the water pump market presents a high growth potential.

- Technology upgrade: With the advancement of science and technology, water pump technology continues to mature and innovate. New water pumps are not only used in traditional fields, but also gradually applied in new fields. For example, high-efficiency energy-saving water pumps, smart water pumps, solar water pumps, etc., improve the efficiency of water pumps and reduce energy consumption.

- Enhanced awareness of environmental protection: Environmental protection has become the focus of global attention, and reducing energy consumption and carbon emissions has become a policy requirement of various countries. Therefore, water pumps with low energy consumption, low noise, and high efficiency have been widely used, such as frequency-adjustable water pumps and intelligently regulated water pumps.

- Automation and intelligent development: With the combination of automation technology and water pump technology, water pumps have begun to realize functions such as remote monitoring, fault diagnosis and automatic adjustment, which improves the safety and reliability of water pumps. At the same time, the application of big data and artificial intelligence also provides new opportunities for the optimal control and intelligent management of water pumps.

- Intensified market competition: With the increase of market demand, the competition in the water pump market is also becoming more and more fierce. Many water pump manufacturers at home and abroad compete in terms of technological innovation, product quality and after-sales service, and the market concentration has increased accordingly.

In general, the water pump market shows a positive development trend in terms of market scale expansion, technological upgrading, environmental awareness improvement, and automation and intelligence. In the future, as the country’s requirements for energy consumption and environmental impact continue to increase, the water pump industry will continue to carry out technological innovation and application expansion to adapt to changes in market demand.

Common water pump questions and answers are as follows:

What should I do if there is noise when the water pump is running?

Answer: The noise may be caused by worn or loose parts inside the pump. You can try to check and tighten loose parts, or replace worn parts.

What should I do if the water pump cannot be started?

Answer: First check whether the power supply is normal and ensure that there is sufficient voltage supply. Second, check that the motor is working properly, it may need to be replaced. It can also be caused by a blockage or malfunction inside the pump, which needs to be cleaned and repaired.

What should I do if there is water leakage when the water pump is running?

A: Water leaks can be caused by worn or damaged seals. You can try to replace the seal or repair it. In addition, it is also necessary to check whether the pipe connection is tight and ensure that there is no water leakage.

What should I do if the water flow decreases when the pump is running?

Answer: It may be caused by pipe blockage or wear of internal parts of the pump. You can try cleaning the pipes or replacing worn parts.

What should I do if the temperature of the water pump is too high?

Answer: The high temperature may be caused by excessive heat generated by internal friction of the water pump, or abnormal cooling system. You can try to check that the cooling system is working properly, clean the cooling system, or replace faulty parts.

What should I do if the water pump starts and stops frequently when it is running?

Answer: It may be caused by incorrect setting or failure of the water pump pressure switch. You can try adjusting the pressure switch settings, or replace a failed pressure switch.

The above are some common water pump problems and answers. If the problem persists, it is recommended to consult professional water pump maintenance personnel for further inspection and repair.

Contact us

Thank you for your interest in YEM Excavator Parts Team! We are a professional excavator accessories team, committed to providing customers with high-quality and reliable excavator accessories solutions.

Our team has years of industry experience and the technical knowledge to accurately identify and resolve various excavator parts issues. Whether you need to replace a damaged part, upgrade an existing accessory or find a specific accessory, we are able to provide you with professional advice and assistance.

As a responsible supplier of excavator parts, we cooperate with many well-known manufacturers to ensure that the provided parts are of excellent quality and reliable performance. Our team can not only provide you with standard excavator accessories, but also can customize according to your specific needs.

We understand that time is of the essence in your excavator operations, so we are committed to providing fast and efficient parts supply services. No matter where you are in the world, we can provide you with the accessories you need in time and ensure that they reach you accurately.

If you are interested in our services or have any needs about excavator accessories, please feel free to contact us. Our team will do our best to provide you with the best service and solve any problems for you. Look forward to working with you!