What is a generator and its basic principles. Importance and role of generators in the energy sector.

A generator is a device that converts mechanical energy into electrical energy. It works on the principle of electromagnetic induction, through the interaction between the relative moving magnetic field and the conductor, to generate electric current.

The basic principle of the generator is Faraday’s law of electromagnetic induction, that is, when a conductor moves relative to a magnetic field, an induced electromotive force will be generated in the conductor, thereby generating a current. A generator usually consists of a rotating magnetic field (generated by magnets or electromagnetic coils) and a fixed coil of conductor (usually a coil wound around an iron core). As the magnetic field rotates, the current in the coil of the conductor changes, creating an alternating current.

Generators play an important role in the energy field. It is the core equipment of the power system, which is used to convert mechanical energy into electrical energy and supply it to society and industrial production. Generators are widely used in energy production fields such as power plants, wind power generation and solar power generation, providing people with a stable and reliable power supply. In addition, generators are also used for emergency power generation, power sources for vehicles, and many other areas of electricity demand. It plays an important role in driving socio-economic development, improving quality of life and promoting the use of sustainable energy.

Excavator generator types

The types of generators commonly used with excavators include:

Diesel Generator (Diesel Generator): One of the commonly used generator types for excavators. It uses diesel as fuel and drives the generator through an internal combustion engine to generate electricity.

Turbine Generator: Some large excavators may use a turbine generator, which uses high-speed rotating turbine mechanical energy to drive a generator to generate electricity.

Hybrid Generator: Some modern excavators may use a hybrid system, which includes a generator and battery combination, as well as renewable energy sources such as solar or wind energy, to achieve efficient use of energy.

These generator types can be selected according to the needs and size of the excavator to provide the required power supply.

How the excavator generator works

The working principle of the generator of the excavator is similar to that of the general generator, which is based on the law of electromagnetic induction.

The working principle of the excavator generator is as follows:

Power source provides mechanical energy: Excavators provide mechanical energy through internal combustion engines or other power sources, such as diesel engines.

Rotating field generation: The rotor (usually the rotor winding) in the generator is connected to the power source, and the rotor rotates to create a rotating field.

Conductor coil induced electromotive force: The relative position of the stator (usually the stator winding) and the rotor in the generator is fixed. When the rotating magnetic field of the rotor intersects the stator, the conductor coil in the stator winding will be affected by the magnetic field to generate an induced electromotive force.

Electromotive Force Generates Current: Induced electromotive force causes current to flow in a coil of conductor, thereby generating electrical energy.

Output current supply power: through the circuit system connected to the excavator, the current output by the generator is supplied to the motor of the excavator, lighting equipment and other electrical equipment to meet the power demand of the excavator.

In this way, the excavator’s generator converts mechanical energy into electrical energy, providing the excavator with the power it needs.

Application areas of excavator generators

Excavator generators are mainly used in the following fields:

Construction Sites: Excavators are commonly used on construction sites for earthmoving, digging, and moving work. The excavator generator provides the required power to drive the excavator to work.

Mines and Quarries: Excavators are used in mines and quarries to extract ore and stone. The generator provides electricity to the excavator, enabling it to perform long hours of work.

Agricultural field: Excavators are used in agriculture for land preparation, irrigation and other agricultural work. The generator provides electricity to enable the excavator to perform various agricultural operations.

Urban infrastructure construction: Excavators are used in urban infrastructure construction, such as road construction, pipe laying, and drainage system construction. The generator provides electricity for the excavator to ensure the smooth progress of the construction work.

Environmental cleanup and waste treatment: Excavators play an important role in environmental cleanup and waste treatment, such as cleaning construction sites, clearing rivers and lakes, handling waste and garbage, etc. The generator provides electricity to the excavator, enabling it to perform cleanup and disposal work.

In a word, excavator generators are used in a wide range of fields, covering construction, mining, agriculture, urban infrastructure and environmental cleaning, etc., providing necessary power support for various jobs

Excavator Generator Selection Guide

Here are a few key factors to consider when choosing an excavator generator:

Power requirements: first determine the electrical power required by the excavator. According to the specifications and usage scenarios of the excavator, determine the required rated power and peak power. Make sure that the selected generator can meet the power needs of the excavator.

Fuel type: Choose the fuel type suitable for the working environment and usage requirements of the excavator. Common fuel types include diesel, gasoline, and natural gas, among others. Consider factors such as fuel availability, cost and environmental impact.

Generator type: Select the appropriate generator type according to the scale and usage requirements of the excavator. Common generator types include diesel generators, turbo generators, and hybrid generators, among others. Consider generator reliability, efficiency and adaptability.

Electrical characteristics: Understand the electrical characteristics of the generator such as voltage, frequency and phase number to ensure compatibility with the electrical system of the excavator.

Reliability and durability: Choose a generator brand and model with high reliability and durability to ensure long-term and stable operation.

Maintenance and Service: Consider your generator maintenance and service needs and choose a supplier that offers reliable after-sales support and service.

Cost-effectiveness: Consider comprehensively factors such as generator price, fuel consumption, maintenance cost and lifespan, and choose a generator with higher cost performance.

When choosing an excavator generator, you can consult our YEM professional generator supplier or engineer to formulate a suitable selection plan according to the specific excavator needs and working environment.

Excavator generator technology development trends

Excavator generator technology is constantly evolving and innovating, here are some current technology trends:

Efficient energy utilization: With the increasing requirements for environmental protection and energy efficiency, the technical trend of excavator generators is to develop in the direction of more efficient energy utilization. For example, using advanced combustion technology and energy recovery systems to reduce energy loss and improve the fuel efficiency of generators.

Clean energy application: As the demand for sustainable energy increases, one of the technological development trends of excavator generators is the shift to clean energy applications. For example, develop renewable energy technologies such as solar power and wind power, and combine them with generator technology to achieve a more environmentally friendly power supply.

Hybrid power system: Another technological development trend of excavator generators is the use of hybrid power systems. This system combines generators, battery packs and other energy technologies to achieve efficient use and optimization of energy through an intelligent energy management system, reducing fuel consumption and emissions.

Automation and intelligence: With the development of automation and intelligence technology, excavator generators also tend to be automated and intelligent. For example, the use of advanced control systems and sensor technologies enables automated operation and monitoring of generators to improve efficiency and safety.

Remote monitoring and maintenance: The development of excavator generator technology also includes the enhancement of remote monitoring and maintenance functions. Through the Internet and Internet of Things technology, remote monitoring, fault diagnosis and maintenance management of generators can be realized, and the reliability and availability of equipment can be improved.

These technological development trends will promote the continuous innovation and progress of excavator generator technology, improve its energy efficiency, environmental friendliness and intelligence level, so as to meet the requirements of future energy demand and sustainable development.

Contact us

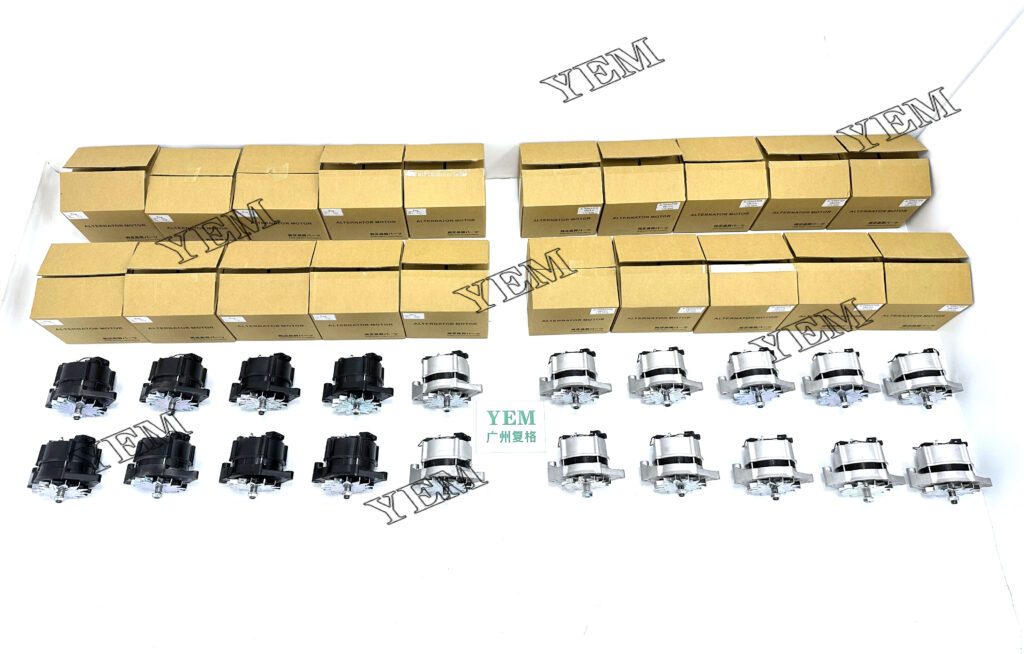

YEM Professional Excavator Parts Team is a dedicated and experienced team specializing in providing high-quality parts for excavators. With our extensive knowledge and expertise in this field, we offer a comprehensive range of parts to meet the diverse needs of our customers.

Whether you require replacement parts for hydraulic systems, engine components, chassis components, or any other excavator component, the YEM team has got you covered. We source our products from reputable manufacturers and ensure that each part meets the highest standards of quality and durability.

What sets us apart is our commitment to exceptional customer service. We understand the importance of timely support and strive to promptly respond to inquiries and requests. Our knowledgeable staff is readily available to help customers identify the correct parts for their specific excavator model and provide installation and maintenance instructions.

To contact the YEM Specialized Excavator Parts team, you can reach us through our website, email, or phone. We are dedicated to building long-term relationships with our customers and are eager to assist you with all your excavator parts needs.