The oil pump plays a vital role in the engine. Its main function is to extract the oil from the oil pan and press it to each lubrication point of the engine to ensure that the parts inside the engine are fully lubricated and cooled.

The principle of the oil pump is as follows:

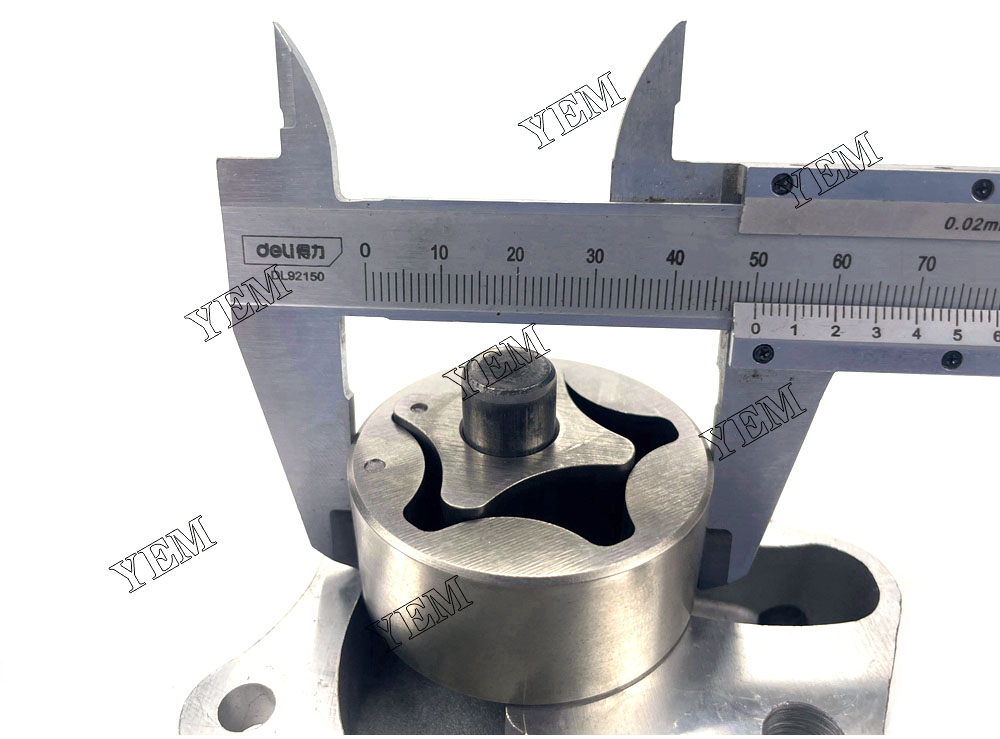

Oil pumping phase: When the engine starts, the oil pump starts to work. It turns an internal rotor or gear through a drive connected to the crankshaft or camshaft. Under the action of the rotor or gear, the oil pump forms a negative pressure in the oil pan, and pumps the oil from the oil pan and oil pool into the pump chamber.

Pressure delivery stage: With the rotation of the rotor or gear, the oil in the pump chamber is pushed into the high-pressure oil pipe or oil channel system. Oil pumps usually have outlet valves or vanes to prevent oil from flowing back into the sump when stopped.

Circulation stage: Once the oil enters the high-pressure oil pipe or oil passage system, it will be sent to various lubrication points of the engine, such as crankshaft bearings, connecting rod bearings, camshafts and cylinder walls, etc. The oil forms a thin film at the lubricating points, reducing friction and heat between metal parts while removing some of the heat and carrying contaminants back to the oil filter for filtration.

To sum up, the function of the oil pump is to extract the oil and press it to each lubrication point of the engine to ensure the lubrication and cooling of the internal parts of the engine, so as to maintain its normal operation and prolong its life.

Different types of oil pumps

There are many different types of oil pumps, here are a few of the common ones:

- Gear pumps: Gear pumps are one of the most common and widely used types of oil pumps. It consists of one or more gears, and the oil is pumped and pressed through the rotation of the gears. This type of pump is simple in structure, reliable, and can provide high pressure.

- Screw pump: The screw pump pumps and presses the oil through the spiral groove between the screw and the casing. They have a large volume and low noise level and are suitable for high head and high temperature environments.

- Turbo pump: The turbo pump uses turbine blades or centrifugal force to draw oil from the inlet and press it to the outlet. This type of pump usually has a higher flow capacity and is suitable for high power engines.

- Piston pump: Piston pump is a pump that pumps and presses oil by moving the piston back and forth in the cylinder. They are typically used in applications requiring higher pressures, such as diesel or high performance engines.

- Worm gear pump: The worm gear pump uses the rotating motion of the worm wheel to draw oil from the inlet and press it to the outlet. They have higher flow rates and lower noise levels and are suitable for certain applications.

These are common types of oil pumps, but different pump types may be selected to meet specific requirements in different engines and applications. Each type of oil pump has its own characteristics and scope of application. Choosing the right oil pump needs to consider the engine’s needs, working conditions and performance requirements.

Oil pump failure and repair

Various failures may occur in the oil pump, the following are some common oil pump failures and corresponding repair methods:

- Pump failure: The oil pump may fail due to problems such as pump body wear, seal failure, and bearing wear during use. Repair methods usually include replacing worn parts, repairing or replacing pump body seals, and making necessary lubrication and adjustments.

- Leakage: The oil pump may leak from the seal of the pump body, resulting in oil loss. Repair methods usually include replacing seals, tightening bolts, adjusting installation positions, etc.

- Noise: The abnormal noise produced by the oil pump during operation may be caused by wear of gears or bearings, loose parts, etc. Repair methods may include replacing worn parts, lubricating parts, adjusting the installation position, etc.

- Clogged or clogged: The oil passages or filters inside the oil pump can become clogged with contaminants, causing poor oil flow. Repair methods usually include cleaning or replacing the oil passage, cleaning or replacing the filter, and ensuring that the oil supply is smooth.

- Driving problem: The driving parts of the oil pump, such as gears and chains, may be worn or broken, causing the pump to fail to work normally. Repair methods usually include replacing worn or broken parts and making proper fit and adjustments.

Note that repairs to oil pump failures should be performed by experienced professionals to ensure proper diagnosis of the cause of the failure and appropriate remedial action. Regular oil pump inspection and maintenance can help prevent breakdowns and prolong the life of your oil pump.

Oil pump selection and replacement

When selecting and replacing an oil pump, there are several key factors to consider:

- Engine requirements: You must first understand your engine requirements, including displacement, power and speed range. Different types of engines may require oil pumps with different flows and pressures. Consult the vehicle or equipment specification sheet to determine the required oil pump parameters.

- Pump type: Common types of oil pumps are gear pumps, turbo pumps and centrifugal pumps. Each type of pump has its advantages and disadvantages and is suitable for different application scenarios. For example, gear pumps are good for high pressure and low flow applications, while centrifugal pumps are good for high flow and low pressure applications. Choose the right pump type according to your needs.

- Brand and quality: It is very important to choose a reliable brand and high-quality oil pump. A quality oil pump is usually better in performance, reliability and durability, and will provide a longer life. Find out about each brand’s reputation and user reviews to choose a reputable manufacturer.

- Installation Compatibility: Make sure the optional oil pump is compatible with your engine or equipment and can be installed correctly. Check the interface size, connection method and installation requirements, etc. to ensure that the pump can be installed correctly and work properly with other systems.

- Replacement Instructions: If replacing an existing oil pump, refer to original equipment manufacturer (OEM) specifications and recommendations for selection. They usually provide guidance and advice on replacement parts, including applicable makes, models, specifications, etc.

When selecting and replacing an oil pump, it is recommended to consult a professional auto mechanic, equipment manufacturer or dealer. They can provide more detailed advice and guidance according to specific needs, and ensure that the selected oil pump meets the requirements and can operate normally.

Oil pump maintenance and upkeep

Regular maintenance and maintenance of the oil pump can ensure its normal operation and prolong its service life. Here are some oil pump maintenance and maintenance recommendations:

Check the quality of engine oil: Regularly check the quality and grade of engine oil. Be sure to use the type and viscosity grade of oil specified by the manufacturer. Replace dirty, thin or aged oil in time.

- Replace the oil filter: Change the oil filter regularly at the manufacturer’s recommended replacement interval. This helps keep contaminants out of the oil pump and lubrication system.

- Keep the oil pump clean: Regularly clean the oil pump and related parts to prevent the accumulated dirt and impurities from affecting the normal operation of the pump. Pay special attention to cleaning the inside of the pump body and each channel.

- Check the pump seal: regularly check whether the seals of the oil pump are intact, and replace worn or aged seals in time. Make sure that the seal between the pump body and other parts is good to prevent oil leakage.

- Lubricating parts: Lubricate the lubricating parts of the oil pump regularly according to the manufacturer’s recommendations. This includes gears, bearings and other moving parts.

- Regular inspection: Regularly check the working status of the oil pump, including noise, vibration and leakage. If abnormalities are found, troubleshoot and repair them in time.

- Pay attention to maintenance standards: When repairing or replacing the oil pump, make sure to use the standards and parts specified by the manufacturer. Follow proper installation and adjustment procedures to ensure proper pump operation.

Note that oil pump maintenance and care may vary by vehicle or equipment. It is best to refer to the manufacturer’s maintenance manual and recommendations for detailed operating instructions for your specific model and application. In addition, regularly taking the vehicle to a professional auto repair center for a comprehensive inspection and maintenance can help to detect and solve potential oil pump problems early.

Technical development trends of oil pumps

The technical development trend of oil pump mainly focuses on the following aspects:

- Electric oil pump: Traditional oil pumps are usually driven by the engine, but with the popularity of electric vehicles and hybrid vehicles, electric oil pumps have gradually become a trend. Electric motor oil pumps allow precise control of oil supply as needed and provide greater energy efficiency and reliability.

- High pressure oil pump: With the continuous improvement of fuel economy and emission requirements of modern automobile engines, the demand for higher pressure oil supply is also increasing. The high-pressure oil pump can provide higher oil pressure to meet the needs of advanced fuel systems such as direct injection systems and turbocharging.

- Variable flow oil pump: Traditional oil pumps usually supply oil at a fixed flow rate, but variable flow oil pumps have the ability to adjust oil flow according to demand. By making real-time adjustments based on parameters such as engine load and RPM, the variable flow oil pump can provide more precise oil supply, reduce energy consumption and improve fuel economy.

- Intelligent control and monitoring: With the development of automobile technology, the application of intelligent control and monitoring systems in oil pumps is becoming more and more common. These systems can monitor parameters such as the working status of the oil pump, oil pressure and temperature in real time, and perform automatic adjustment and fault diagnosis as needed.

- Improvement of materials and lubrication technology: The continuous development of new materials and lubrication technology also plays an important role in improving the performance of oil pumps. For example, the use of bearings and seals with more wear-resistant and high-temperature-resistant materials, as well as the use of advanced lubrication technology, can reduce friction losses and energy consumption of oil pumps.

- Lightweight design: The pursuit of higher energy efficiency and reduced emissions has driven the lightweight design of oil pumps. Through the use of lightweight materials and structural optimization, the weight and inertia of the oil pump can be reduced, improving overall efficiency.

Overall, the technical development trend of oil pumps is towards more efficient, intelligent and environmentally friendly. These innovations will help improve the performance and reliability of automotive engines and meet increasingly stringent emissions and energy efficiency requirements.

Contact us

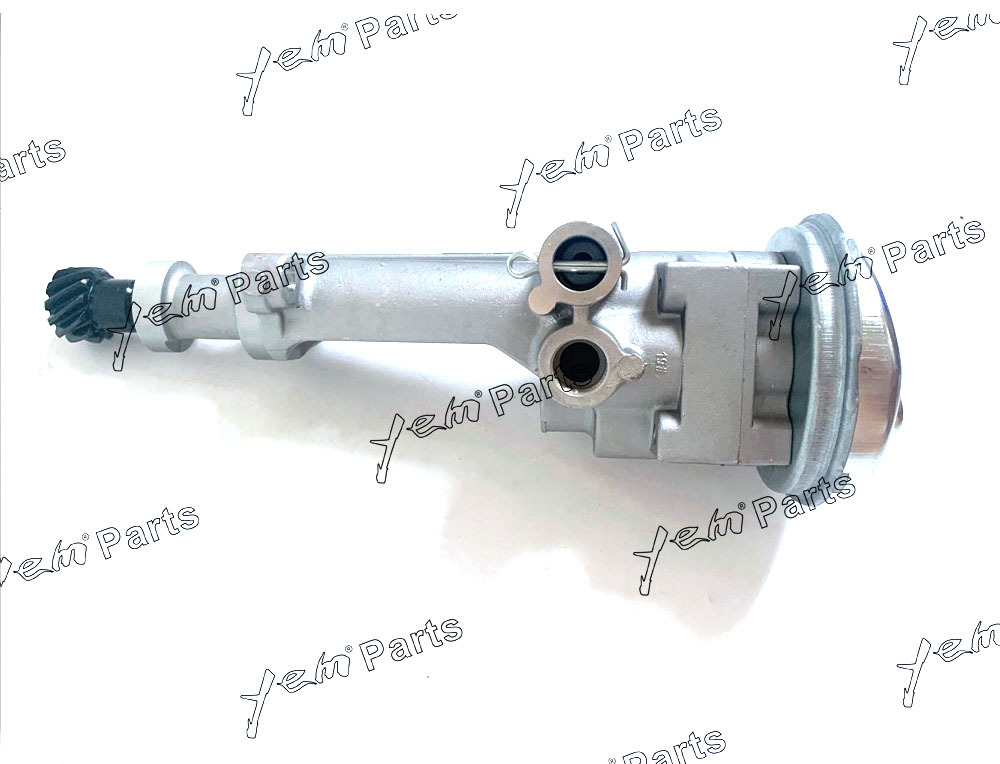

Welcome to the YEM professional excavator parts team! We are a dedicated group of experts specializing in providing high-quality and reliable excavator parts for all your construction needs. With years of experience in the industry, we have established ourselves as a trusted supplier of top-notch components for various excavator models.

Our team consists of skilled technicians, engineers, and customer service professionals who are committed to delivering exceptional service and ensuring customer satisfaction. We understand the importance of having reliable equipment on the job site, and that’s why we strive to offer a comprehensive range of excavator parts that meet the highest standards of quality and performance.

Whether you need replacement parts for routine maintenance or emergency repairs, our team is here to assist you. We work closely with leading manufacturers and suppliers to source genuine and OEM (Original Equipment Manufacturer) parts, ensuring compatibility and durability. From hydraulic cylinders and pumps to undercarriage components and attachments, we have a wide selection of excavator parts to cater to your specific requirements.

What sets us apart is our attention to detail and commitment to excellence. Our team conducts thorough inspections and quality checks on all parts to ensure they meet stringent industry standards. We also provide expert guidance and technical support to help you choose the right parts for your excavator model and application.

At our company, we prioritize customer satisfaction above all else. We strive to offer competitive pricing, prompt delivery, and excellent after-sales service. Our knowledgeable customer service representatives are available to answer any queries you may have and provide assistance throughout the purchasing process.

When it comes to excavator parts, trust our professional team to deliver the reliability and performance you need. Contact us today to discuss your requirements and experience the difference of working with a dedicated and experienced excavator parts team.