9 Bad Diesel Fuel Injector Symptoms

Summer is the harvest season for farmers.

They spend a lot of time working. The hot weather not only poses a threat to farmers, but also has a negative impact on fuel injectors. When working in a high-temperature environment, fuel injectors are prone to overheating, thereby affecting their performance and working efficiency. Therefore, in this article, some useful techniques to prevent fuel injectors from overheating are presented to you. Time waits for no one. Read it now! #Fuel Injectors# #Overheating Prevention#

Exploring Yempart in depth: Brand videos interpret brand DNA

Are you ready to have a cold beer, listen to wonderful music, and relax. But there is one thing blocking your way – the off-road machinery is damaged. Don’t worry, YEMParts will help you solve this problem. We understand the importance of worry free Fridays, which is why we are committed to providing OEM quality aftermarket parts to get your machinery running again.

When you encounter bad fuel injector symptoms, it’s crucial to know that all car components work together for normal and efficient driving. The fuel injector is vital. Its proper operation directly affects engine performance, fuel efficiency, and exhaust emissions. Adverse symptoms need your attention. For example, vehicle power could be reduced. Pressing the accelerator pedal results in slow and weak acceleration. Fuel consumption might increase. Engine operation could be unstable with vibrations and rpm fluctuations. Exhaust emissions might exceed standards with a pungent smell. As a professional accessories seller, our company provides high-quality fuel injector accessories. When your vehicle has these symptoms, timely replacement is key. Our parts undergo quality testing to restore your vehicle’s condition. Choose our accessories for reliable quality and service. Let’s safeguard your car together.

Recent Posts

- Complete Guide to Injector Fault Diagnosis and Repair.

- Technological breakthrough and application of new injector

- The secret to optimizing injector performance and improving fuel efficiency.

- Maintenance tips and common misunderstandings of ejectors. Characteristics and applicable scenarios of different types of ejectors.

related information

Can l still drive my car if my fuel injector is broken?

Can l still drive my car if my fuel injector is broken?

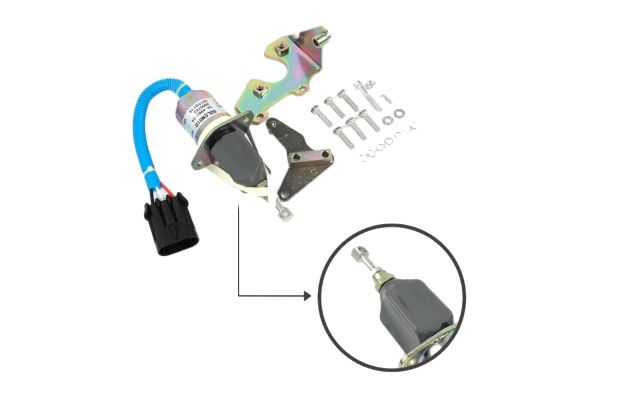

9 Symptoms of a Faulty Fuel Shutoff Solenoid.

9 Symptoms of a Faulty Fuel Shutoff Solenoid.

How to Clean Diesel Engine Injectors.

How to Clean Diesel Engine Injectors.

What causes fuel injector failure?

1.Fuel quality issues:

Long-term use of low-quality fuel with many impurities, high water content or excessive colloid will cause impurities and undesirable components to accumulate in the fuel injector. These tiny particles may clog the spray hole, affect fuel atomization and combustion, change the injection flow and pressure, destroy the normal working mode, and eventually damage the injector.

2.Carbon deposit accumulation:

During the continuous operation of the engine, carbon deposits gradually form in the combustion chamber due to factors such as incomplete combustion. Carbon deposits adhere to the surface of the injector nozzle and the internal channel, occupying the injection space, hindering fuel injection, increasing the workload of the injector, and gradually reducing its performance until it is damaged.

3.Wear and aging:

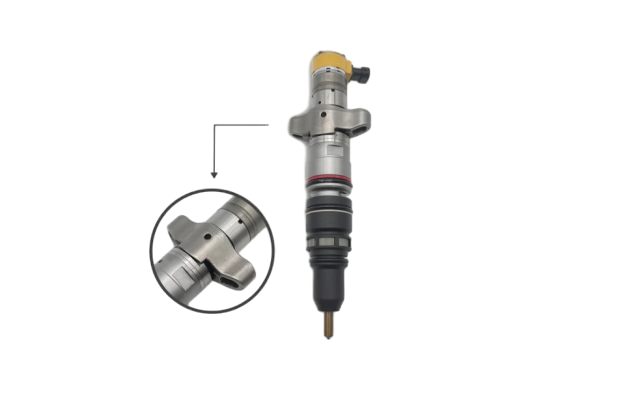

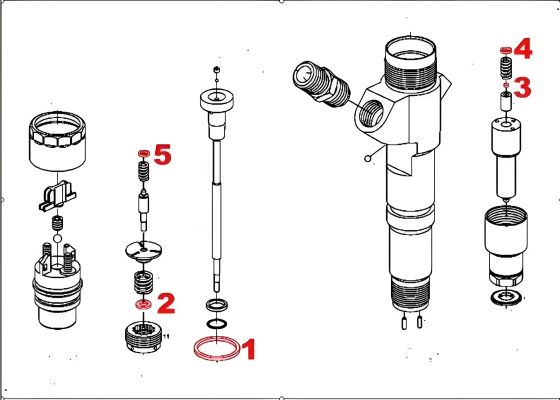

There are many precision parts inside the injector, such as seals, needle valves, etc. As the use time increases and the number of injections increases, the parts will wear out. Failure of the seal will cause fuel leakage, and wear of the needle valve will change the shape and amount of injection. In addition, long-term use will also cause aging of the parts, such as weakening of the spring elasticity, affecting the normal operation of the injector and eventually causing damage.

4.circuit failure:

The normal operation of the fuel injector depends on a precise electronic control system. When the circuit is short-circuited, open-circuited or the voltage is unstable, the injector may not receive the correct control signal or the signal strength may be insufficient, resulting in deviations in the injection timing and injection amount, or even failure to work properly. Long-term abnormal conditions can easily damage it.

Therefore, regular maintenance, using high-quality fuel, avoiding high-temperature environments, ensuring a good electrical system, and proper installation and maintenance are all key factors in extending the life of your fuel injectors.

Diesel Fuel Injector Failure Symptoms

1.Engine power loss:

When a fuel injector fails, thereby starving one or more cylinders of the necessary fuel supply, the engine can experience a rapid and significant loss of power. This situation can have a detrimental effect on the engine’s ability to generate the desired power output. The failure of the fuel injector to provide an adequate amount of fuel to the cylinders disrupts the normal combustion process within the engine. As a consequence.

2.Reduced fuel economy:

Reduced fuel lfitdiencymay take place fone or more fueliniectors are not functioning at an optimalevel or are not operating eficienty .This sitation can gwe rise to varousisuessuch as wasted fuel or incomplete combustion.Wwhen the fuel injectors are not performing as they should,the amount and timing of fuel deliveryto the engine cylinders may beincorect. This can result in an imbalance inthefuelair mixture,causing the fuel to be either consumed in exces without generatingthe coresponding power orto not combustcompletely.such ineitciencies in the fuel iniection proces canlead to a decreasein the overalfuel economy ofthe vehicle. Thefuelthat is not being utilzed eftectively is essentiabeing wasted, and the incomplete combustion can further contribute to reduced power outout and increased emissions

3.Stalling Engine:

If one or more injectors stop working entirely, the chances are high that the engine will stall when it is idling, especially when deceleration occurs. This is because the absence of fuel injection in one or more cylinders disrupts the balance and smooth operation of the engine during these low-speed conditions. Particularly during deceleration, when the engine’s demand for fuel is already reduced, the complete failure of one or more injectors can tip the balance and cause the engine to lose its ability to maintain a stable idle. Regular stalling in such circumstances is a strong indicator of serious problems within the combustion process. It suggests that there are significant flaws or malfunctions that are preventing the efficient and consistent burning of the fuel-air mixture. This could be due to a variety of factors such as blocked or damaged fuel lines, faulty sensors providing incorrect information to the engine control unit, or problems with the ignition system that prevent proper combustion. The consistent stalling should be seen as a serious warning sign that requires immediate attention and a comprehensive diagnostic assessment to identify and rectify the underlying issues within the combustion process and restore the engine’s normal operation.

4.Rough idling:

A failing injector causes difficulties for the engine during idling. Instead of the usual smooth purr or rumble, it leads to rough, sputtering, and shaking idle behavior. When an injector close to failure, it cannot supply fuel precisely and consistently to the combustion chambers. This inconsistent fuel delivery disrupts the smooth operation of the engine at idle speeds, causing intermittent and uneven power strokes within the cylinders. This results in a sputtering sensation, and the engine may shake and vibrate noticeably. This erratic idle indicates a problem with the injector and potential issues in the fuel delivery system and combustion process. If not addressed promptly, it can cause discomfort, increased fuel consumption, and damage to other engine components. Quick diagnosis and appropriate repair or replacement of the failing injector are necessary to restore a smooth idle and optimal engine.

5.Increased Exhaust Emissions:

Leaking fuel injectors can pose a significant problem by introducing an excessive amount of fuel into the combustion chamber. This leads to the creation of a rich fuel-air mixture and leaves unburned fuel within the system. As a consequence, black smoke is emitted from the tailpipe. When fuel injectors leak, they fail to control the precise amount of fuel being injected. The surplus fuel upsets the ideal balance of the fuel-air mixture, making it overly fuel-rich. This imbalance hinders complete combustion, causing unburned fuel to be expelled through the exhaust system, manifesting as black smoke. The presence of black smoke emissions is a clear indication of an anomaly in the fuel injection process and a potential issue with the injectors themselves. It not only indicates poor fuel efficiency but also may suggest damage to other components of the engine and contribute to increased pollution. Prompt identification and repair of the leaking fuel injectors are crucial to restore proper fuel injection, improve combustion efficiency, and eliminate the black smoke emissions for a cleaner and more efficient engine operation.

6.Engine Misfire:

Insufficient fuel injection can cause significant disruption to the delicately balanced fuel-air mixture within the combustion chamber. This imbalance leads to misfiring, a phenomenon where the combustion process fails to occur properly at the intended moments. The consequence of this misfiring is that the engine stutters and judders as it misses revolutions. The inconsistent and incomplete combustion events cause the engine’s power delivery to become erratic, with noticeable hesitations and jerks in its operation. This disruption not only affects the smooth running of the engine but also has implications for its overall performance, fuel efficiency, and emissions. It may indicate issues with the fuel injectors themselves, problems in the fuel supply system, or faults in the engine’s control mechanisms that regulate fuel injection. Prompt diagnosis and resolution of the problem causing insufficient fuel injection are essential to restore the engine’s smooth and efficient operation, ensuring reliable performance and minimizing potential damage to engine components over time.

7.Dancing RPM Needle:

Malfunctioning injectors can have a detrimental effect by disrupting the crucial fuel – a situation where the combustion process doesn’t occur as it should at the correct intervals. Consequently, this results in erratic engine RPMs (Revolutions Per Minute). This irregularity is clearly noticeable through the volatile movements of the RPM needle on the dashboard gauge. The unstable behavior of the RPM needle indicates that the engine is not operating smoothly and consistently. It suggests that there are issues with the fuel supply and combustion process due to the malfunctioning injectors. This can have implications for the engine’s performance, fuel efficiency, and overall drivability. It is essential to identify and address the injector malfunction promptly to restore the proper fuel-air mixture, stabilize the engine RPMS, and ensure a reliable and efficient engine operation.

8.checking Engine Light:

A malfunctioning fuel injector can have a considerable influence on the vehicle’s on-board diagnostics. When it fails to operate correctly, it can bring about numerous problems in the engine’s working process. This malfunction may set off a chain of reactions within the vehicle’s intricate systems, eventually leading to the lighting up of the check engine light on the dashboard. The incorrect functioning of the fuel injector could cause an imbalance in the fuel-air mixture, influencing the combustion process and the overall performance of the engine. It might result in incomplete combustion, a decrease in power output, and an increase in emissions. These irregularities are picked up by the vehicle’s sensitive sensors and monitoring systems, which then send signals to trigger the check engine light as a cautionary sign for the driver. It should be emphasized that the appearance of the check engine light does not directly point to the precise problem with the fuel injector. It merely alerts the driver that there is a matter that demands attention and further examination by a competent mechanic or through the use of specialized diagnostic equipment. Neglecting this warning might potentially cause more serious harm to the engine and result in extensive repairs later on.

9.Fuel Odors:

A leaking or malfunctioning fuel injector can give rise to a rather troublesome issue where fuel odors become detectable either within the vehicle’s cabin or in the area surrounding the engine bay. When a fuel injector is not functioning as it should or is experiencing a leak, it can allow fuel to escape in an uncontrolled manner. This escape of fuel can result in the vaporization of the fuel, and the resulting fumes can easily permeate the nearby spaces. If the leak is significant, the fuel odor can be quite pronounced and persistent, making the driving experience unpleasant and potentially raising concerns about safety and fuel efficiency. In some cases, the fuel odors may be accompanied by other symptoms such as a decrease in engine performance, increased fuel consumption, or visible signs of fuel leakage around the injector itself. It is crucial to address such issues promptly as a leaking fuel injector not only poses environmental risks but also poses a fire hazard and can lead to more severe damage to the engine if left unchecked. Early detection and proper repair or replacement of the faulty fuel injector can prevent further complications and ensure the vehicle operates safely and efficiently, without the nuisance of persistent fuel odors.

What Happens When Fuel injectors Go Bad?

When fuel injectors go bad, it can have a profound and far-reaching impact on various aspects such as engine performance, fuel efficiency, and emissions. It is of utmost importance to promptly and without delay check the condition of fuel injectors, and take appropriate measures such as repairing or replacing them. This not only helps to prevent further damage to the engine but also ensures that the vehicle operates at its optimum level.

How to Prevent Fuel injector Problems

Preventing problems with diesel engine fuel injectors requires focusing on two critical measures.

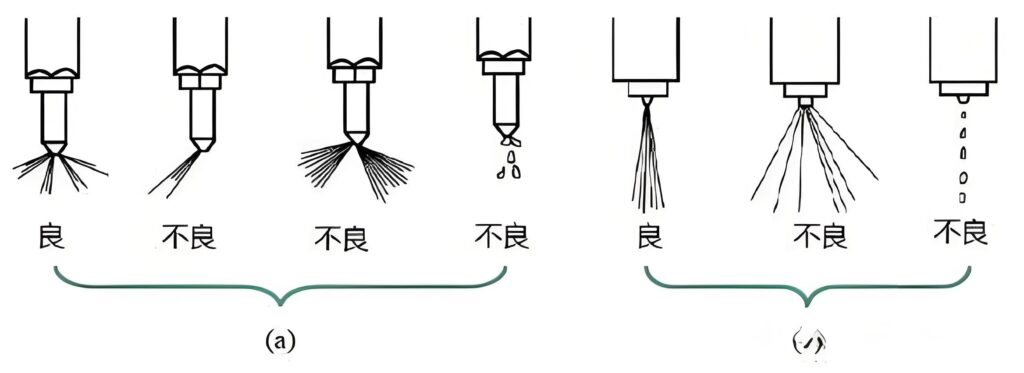

Firstly, opt for high-quality diesel fuel from trusted sources to minimize the risk of injector clogging and damage from dirt and debris, thus ensuring the engine’s health. Selecting reliable fuel suppliers is of utmost importance as it ensures that the diesel fuel contains fewer impurities that could potentially cause harm to the fuel injectors. For instance, well-known fuel depots with a proven track record often have rigorous quality control processes to guarantee the purity of the diesel they provide. This helps prevent the build-up of contaminants within the injectors, reducing the chances of blockages and subsequent performance issues in the engine.Secondly, adhere strictly to the manufacturer’s recommended maintenance schedule and servicing intervals. This involves having the diesel engine inspected and serviced at the prescribed times to keep the fuel injection system in prime condition. The manufacturer’s guidelines are based on extensive research and testing, and adhering to them precisely can greatly extend the lifespan of the diesel engine fuel injectors. For example, regular checks for fuel pressure, injector spray patterns, and timely cleaning or replacement as necessary can prevent minor issues from escalating into significant problems. Disregarding these recommendations could result in premature wear and tear of the injectors, leading to reduced fuel efficiency and potential damage to the engine.

Should You Repair Fuel injector Or Get It Replaced?

When faced with the decision of whether to repair or replace your fuel injector, consider performing diagnostic checks to determine if it’s malfunctioning or simply dirty. If the injector is malfunctioning, replacement is advisable, but if it’s just dirty, a thorough cleaning should suffice.

Welcome, new member!