- what causes piston ring failure

- Wear and Tear

- Normal Wear: As the engine operates, friction between the piston rings and cylinder walls gradually wears down the piston rings. This type of wear is inevitable but can be slowed down through proper lubrication and regular maintenance.

- Abnormal Wear: The presence of contaminants such as dust and metal particles in the engine or poor-quality oil can accelerate the wear of piston rings.

- Poor Lubrication

- Insufficient or Poor-Quality Oil: Oil is crucial for internal lubrication within the engine. Insufficient oil levels or oil that does not meet the required specifications can compromise the lubrication between piston rings and cylinder walls, leading to increased wear.

- Oil Pump Malfunction: The oil pump is responsible for distributing oil to all lubricated parts of the engine. If the oil pump fails, oil supply is affected, potentially causing inadequate lubrication of piston rings.

- High Temperatures

- Engine Overheating: Prolonged high-load operation or malfunctioning cooling systems can cause engine overheating. High temperatures can thin the oil, reducing its lubricating properties and exacerbating piston ring wear.

- Excessive Combustion Chamber Temperatures: High temperatures within the combustion chamber can also subject piston rings to thermal stress, leading to deformation or failure.

- Assembly Issues

- Improper Assembly: During engine repairs or piston ring replacements, incorrect assembly (e.g., excessive or insufficient piston ring gap, wrong installation orientation) can result in piston ring failure.

- Poor-Quality Components: Using substandard piston rings or related components can also contribute to piston ring failure.

- Other Factors

- Fuel Quality: Impurities and moisture in fuel can damage piston rings.

- Engine Design Flaws: Certain engine designs may have inherent flaws that make piston rings prone to failure under specific operating conditions

Symptoms of Bad Piston Rings

- Increased Oil Consumption and Blue Smoke

- Worn or damaged piston rings can cause oil to leak into the combustion chamber, leading to significant oil leakage into the cylinders. This results in blue smoke from the exhaust pipe, especially noticeable when the engine is first started and the cylinder temperature hasn’t fully risen.

- Abnormal Exhaust Emissions

- Bad rings allow combustion gases to escape from the top, causing exhaust emissions to appear smoky or discolored (e.g., blue or black).

- Reduced Engine Power

- Reduced sealing performance of the piston rings causes pressure loss within the cylinder and creates gaps between the ring surface and cylinder wall. During combustion, these gaps allow high-pressure gases to escape into the oil pan. Consequently, engine power output decreases, and the oil becomes contaminated, reducing its performance and lifespan. Severe wear or sticking can also make the engine difficult to start and cause persistent power loss.

- Increased Engine Noise

- Larger gaps between the piston and cylinder wall result in increased noise. This noise can include knocking, friction noise, vortex noise, and airflow noise.

- White Smoke

- Bad piston rings can allow a large amount of coolant to enter the combustion chamber, resulting in white steam in the exhaust.

Replacement Guide for Piston Rings

- Remove the Cylinder Head and Oil Pan

- This will give you access to the pistons.

- Disassemble the Engine Block

- Take care not to damage the cylinder surface.

- Remove the Connecting Rod End

- Extract the piston and connecting rod from the top of the cylinder. Carefully inspect the piston, connecting rod, and other parts for abnormal wear.

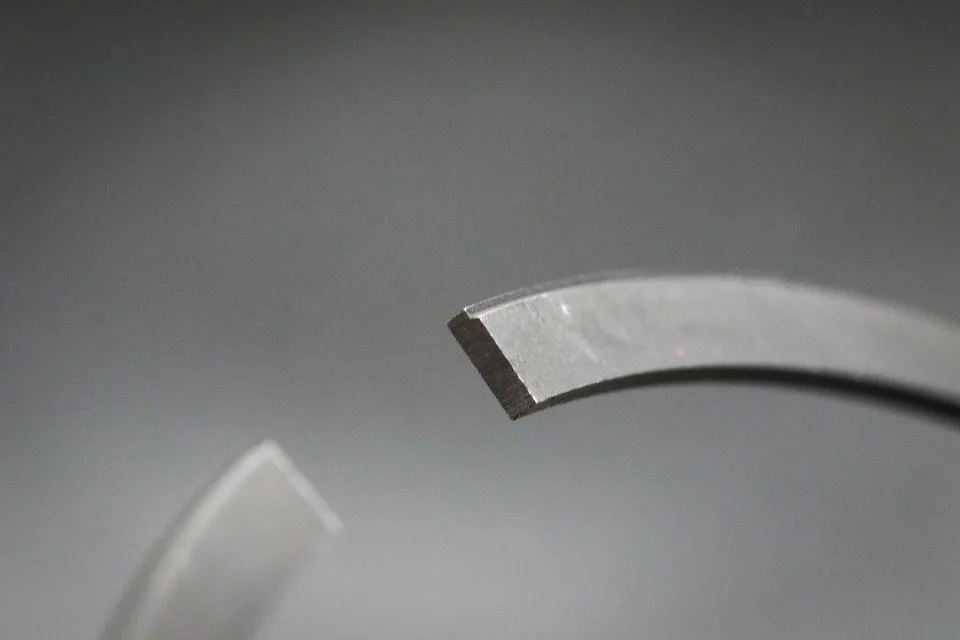

- Remove the Old Piston Rings

- Use a piston ring removal tool to carefully take off the old rings.

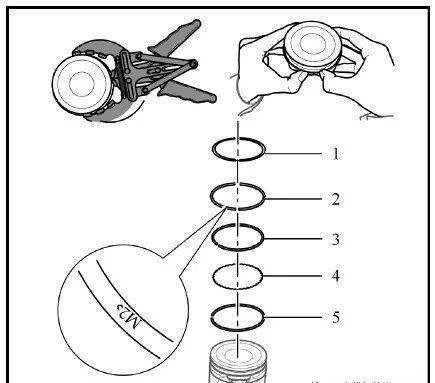

- Install the New Piston Rings

- Use a piston ring compressor to compress and install the new rings onto the piston. Ensure each ring is correctly installed and can move freely.

- Reinstall the Piston and Connecting Rod Assembly

- With the new piston rings installed, place the assembly back into the cylinder.

- Conduct a Full Engine Tune-Up and Test Run

- Ensure everything is working correctly and the engine is performing optimally.

Piston Ring Replacement Cost

- The cost of replacing piston rings in off-road machinery generally ranges from $200 to $500, depending on the engine size and piston ring specifications.

- If you opt for OEM (original equipment manufacturer) parts and have the replacement done by a professional repair shop, the cost can be as high as $500.

- However, if you choose aftermarket piston ring kits and perform the replacement yourself, the cost can be controlled at around $200. This approach can reduce expenses by approximately 30% to 50%.

Contact US for Professional Help

Experienced drivers can easily detect piston ring failures, while new drivers may find it challenging. However, addressing these issues promptly is crucial for extending the engine’s lifespan.

At YEMPARTS, you can find the necessary parts to minimize engine wear and repair damaged components. If you can’t find what you need, please feel free to contact us. Our professional customer service team will be glad to help you. For more aftermarket parts, please visit theYEMPARTS site