The Kubota fuel injection pump achieves precise control of the engine’s fuel supply by controlling the injection time and fuel injection volume of the injector, which is accomplished through the electronic control unit (ECU). Here’s a detailed explanation of the process:

- Sensor data collection:

- When the engine is working, various sensors will continuously monitor and collect the engine’s operating status, including speed, load, temperature, air pressure and other parameters.

- ECU calculation control strategy:

- The ECU of the Kubota fuel injection pump will calculate the required fuel amount and injection time under the current working state based on the data collected by the sensor and the preset control strategy.

- Injector control signal output:

- The ECU generates corresponding control signals based on the calculation results to control the opening and closing time of the fuel injector and the amount of fuel injection. These signals are transmitted to the fuel injectors via electrical lines.

- Fuel injection from the fuel injector:

- The fuel injector opens and closes on time according to the control signal of the ECU to achieve fuel injection. Precise control of injection time and amount ensures that fuel is injected into the engine at the appropriate time and amount.

- Fuel combustion:

- After the injected fuel is mixed with air, it is burned in the cylinder and drives the engine to operate normally.

Through the above steps, Kubota fuel injection pump can achieve precise control of engine fuel supply. This precise control can not only improve the combustion efficiency and power performance of the engine, but also reduce emissions and fuel consumption, and improve the performance and economy of the entire vehicle.

Optimizing Kubota fuel injection pump performance is key to ensuring efficient engine operation. Here are some suggestions for adjusting spray parameters, cleaning and maintenance, etc.:

- Regular cleaning and maintenance:

- Regularly clean the fuel injector and filter in the fuel injection system to ensure that the fuel injection channel is clear to avoid blockage or pollution that affects the fuel injection effect. At the same time, pay attention to replacing the fuel filter regularly to maintain the purity of the fuel.

- Optimize fuel injection parameters:

- Adjust fuel injection parameters, such as injection time and injection volume, according to the actual usage and driving habits of the vehicle. This can be done by a professional auto service technician or vehicle performance tuner to ensure the engine is getting the best fuel supply.

- Use high-quality fuel:

- Choosing high-quality fuel can reduce contamination of the fuel injection system by residues and impurities, improve fuel combustion efficiency, and thereby optimize the performance of the Kubota fuel injection pump.

- Maintain normal engine operating temperature:

- Pay attention to maintaining the normal operating temperature of the engine. Too low a temperature may lead to incomplete fuel combustion and affect engine performance. Regularly check the working status of the engine cooling system and radiator to ensure that the engine can run at a suitable temperature.

- Repair faults promptly:

- If the Kubota fuel injection pump or related parts are found to be faulty, they should be repaired or replaced in time. Delayed processing may lead to more serious problems that affect the performance and safety of the entire vehicle.

- Check system pressure regularly:

- Regularly check the operating pressure of the fuel injection system to ensure that the pressure is stable and within the normal range. Too high or too low pressure may affect the fuel injection effect and engine operating status.

Through the above methods, the performance of Kubota fuel injection pump can be effectively optimized, and the combustion efficiency, power output and vehicle performance of the engine can be improved. At the same time, regular maintenance can also extend the service life of the fuel injection system and reduce the occurrence of failures and damage.

Here are some common causes and solutions for Kubota fuel injection pump failures to help you quickly identify and solve the problem:

- The fuel injection nozzle is clogged:

-Cause: The fuel injection nozzle is clogged due to poor oil quality or too long use time.- Solution: Clean or replace the clogged fuel injector regularly to ensure that the fuel injection channel is clear.

- Fuel leakage:

-Cause: Injector seal failure, fuel pipeline connection loose or damaged, etc.- Solution: Check and replace poorly sealed injectors or pipes to ensure the fuel system is intact.

- Unstable pressure:

- Cause: High-pressure pump failure, pressure regulator failure, etc.

- Solution: Check the high-pressure pump and pressure regulator, repair or replace damaged parts.

- Electronic control unit (ECU) failure:

- Reason: ECU damage, electrical connection problem, etc.

- Solution: Check the ECU and its electrical connections, repair or replace damaged parts.

- Insufficient fuel supply:

-Cause: Fuel pump failure, fuel filter clogged, etc.- Solution: Check and repair the fuel pump or replace the clogged fuel filter.

- Inaccurate fuel injection time or fuel injection amount:

-Cause: ECU control algorithm error or sensor failure, etc.- Solution: Check sensor status and ECU control algorithm, calibrate or adjust as needed.

- Fuel system pollution:

- Cause: Contamination caused by long-term use of low-quality fuel or improper cleaning of the fuel system.

- Solution: Clean the fuel system regularly, replace filters, and use high-quality fuel.

- System voltage problem:

- Cause: Unstable power supply or loose electrical connection.

- Solution: Check the power connections and voltage stability to ensure the electrical system is functioning properly.

By identifying these common causes of failure and taking appropriate solutions, you can effectively repair Kubota fuel injection pump problems and ensure normal engine operation. If you encounter a more complex fault or cannot solve it by yourself, it is recommended to seek professional car maintenance technical support.

Kubota fuel injection pumps are widely used in different industries, mainly including the automotive industry, aerospace industry, shipbuilding industry, industrial machinery and other fields.

- Automobile industry:

- In the automotive industry, Kubota fuel injection pumps are one of the key components in modern internal combustion engine vehicles. As vehicle performance, fuel efficiency and emissions standards continue to improve, so does the demand for fuel injection technology. As one of the leading manufacturers of fuel injection systems, Kubota has a wide range of applications and market shares in the automotive industry.

- Aerospace field:

- In the aerospace field, the performance requirements of fuel injection systems are extremely high, and there are strict requirements for fuel supply and control accuracy. Kubota’s fuel injection technology is widely used in aircraft engines, providing reliable power systems for aircraft.

- Shipbuilding industry:

- In the marine industry, especially in large ships and marine engines, fuel injection systems also play an important role. Kubota’s fuel injection pumps are widely used in the shipbuilding industry to provide efficient and stable power output for ships.

- Industrial machinery:

- In addition to the transportation field, Kubota’s fuel injection technology is also widely used in industrial machinery, such as generator sets, construction machinery, etc. These equipment also have strict requirements for efficient fuel utilization and power output, and Kubota’s technology can meet these needs.

In terms of market development trends and prospects, as the automotive industry develops towards electrification, intelligence and lightweight, fuel injection technology will still maintain an important position, especially in fields such as hybrid and fuel cell vehicles. In addition, the demand for high-performance fuel injection systems in the aerospace industry will continue to increase. As the global industrialization process advances, the requirements for high efficiency and energy saving in the industrial machinery field will also increase. Kubota’s fuel injection technology is expected to play a greater role in these fields.

In general, Kubota fuel injection pumps have broad application prospects in multiple industries. With continuous technological innovation and growing market demand, its market position and influence are expected to be further improved.

Here is a detailed guide on how to properly install, tune and maintain a Kubota fuel injection pump, including troubleshooting and solutions to common problems:

- Installation Guide:

- Before installing the Kubota fuel injection pump, please ensure the following:

- Ensure that the installation location is suitable and protected from overheating, vibration or other external influences.

- Clean the installation location to ensure there are no impurities or dirt that may affect the installation quality.

- Check the mounting hardware and seals to ensure they are intact.

- When installing, please follow the instructions in the installation manual or instructions provided by Kubota to ensure correct and stable installation.

- Make sure to connect the wires correctly to avoid incorrect polarity or short circuit.

- Debugging process:

- After installation, please make sure all connections are correct and tight before commissioning.

- After starting the engine, observe the operation of the fuel injection pump and check for abnormal noise or leakage.

- Use diagnostic tools to check the operating parameters of the injection pump, such as pressure, fuel injection volume, etc., to ensure they are within the normal range.

- Adjust necessary parameters such as fuel injection volume, injection time, etc. to meet engine performance and emission requirements.

- Maintenance Guide:

- Regularly check the connecting parts and seals of the fuel injection pump to ensure that they are not loose or worn.

- Clean the fuel injection pump and its surrounding area regularly to avoid accumulation of dust or debris that may affect its working performance.

-Replace the fuel filter regularly to ensure clean fuel and avoid clogging the fuel injectors or damaging the fuel system. - Regularly check the working parameters of the fuel injection pump, such as pressure, fuel injection volume, etc., to ensure normal operation.

- Troubleshooting and solutions to common problems:

- If you find that the fuel injection pump is working abnormally or malfunctioning, please first check whether there is a power supply problem and eliminate the electrical fault.

- Check whether the fuel injector is clogged and clean or replace it if necessary.

- Check whether the fuel pump is working properly and repair or replace if necessary.

- If you find fuel leakage, check whether the seal is intact and replace it if necessary.

- If the fuel injection amount or injection time is found to be inaccurate, please check the sensor status and ECU control algorithm, and calibrate or adjust as necessary.

By following the above guidelines, you can ensure the correct installation, commissioning and maintenance of the Kubota fuel injection pump to ensure its long-term stable and reliable operation. If you encounter complex problems or cannot solve them, please seek professional car repair technical support in time.

To ensure the long-term stable operation of the Kubota fuel injection pump, it is recommended to follow the following maintenance cycles and methods:

- Regular cleaning and inspection:

- It is recommended to clean and inspect the fuel injection pump every 3 months or every 3000 to 5000 kilometers driven.

- Clean the fuel injection pump and its surrounding area to remove accumulated dust, dirt and debris to ensure proper operation.

- Check the connecting parts and sealing rings of the fuel injection pump to make sure they are not loose or worn, and replace them if necessary.

- Replace the fuel filter regularly:

- Regular replacement of the fuel filter is essential to keep the fuel system clean and operating stably.

- It is recommended to replace the fuel filter every 6 months or every 10,000 kilometers driven, or according to the vehicle manufacturer’s recommendations.

- Regularly check working parameters:

- Every time you perform routine maintenance on your vehicle, you should check the operating parameters of the fuel injection pump, such as pressure, fuel injection volume, etc.

- Ensure that the working parameters are within the normal range. If there are any abnormalities, make timely adjustments or repairs.

- Regular calibration and adjustment:

- It is recommended to calibrate and adjust the fuel injection pump every 12 months or every 20,000 kilometers driven.

- Calibrate and adjust the parameters of the fuel injection pump according to the vehicle manufacturer’s recommendations or the guidance of professional technicians to ensure its performance and efficiency.

- Solve problems promptly:

- If you find that the fuel injection pump is working abnormally or malfunctioning, please investigate and repair it in time to avoid further deterioration of the problem.

- Seek professional car repair technical support if the problem cannot be solved by yourself.

Through the above maintenance cycles and methods, the long-term stable operation of the Kubota fuel injection pump can be effectively ensured and its service life can be extended. At the same time, it is recommended to refer to the vehicle manufacturer’s recommendations or consult professional technicians when performing any maintenance or replacement operations to ensure correct and effective operations.

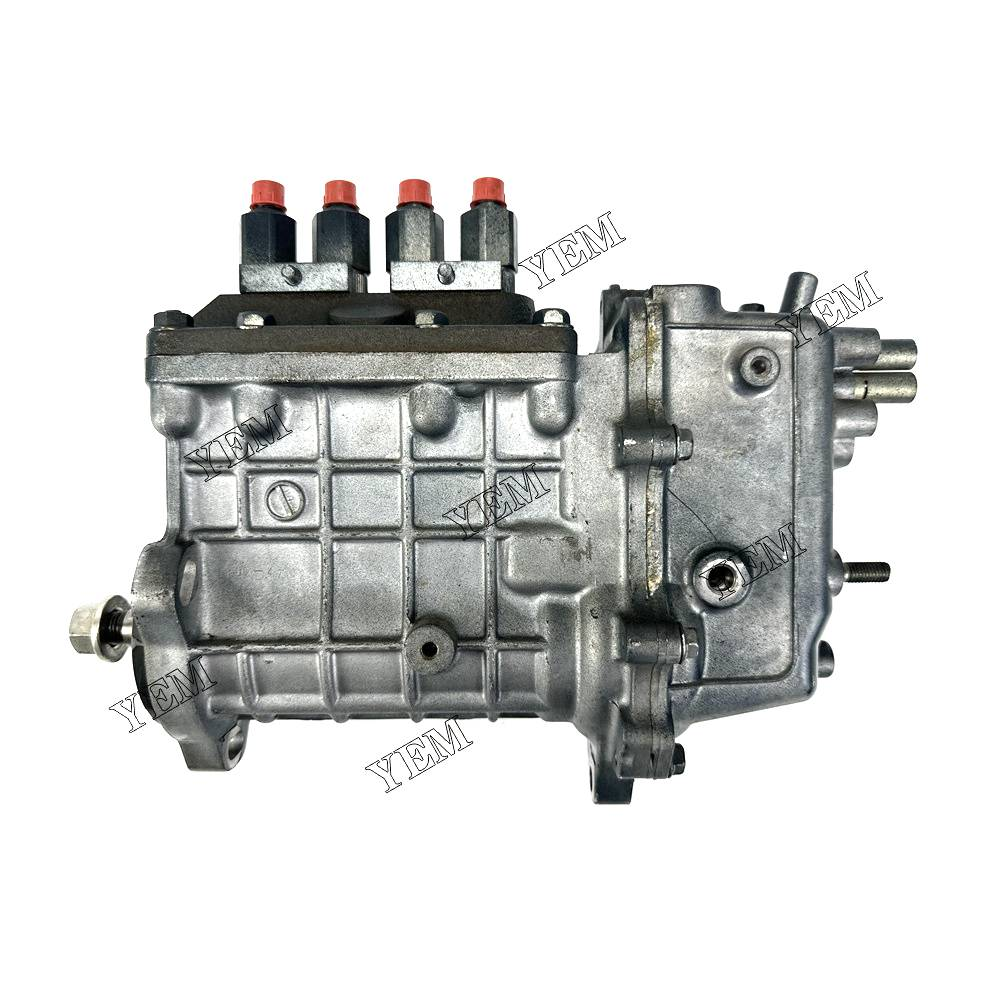

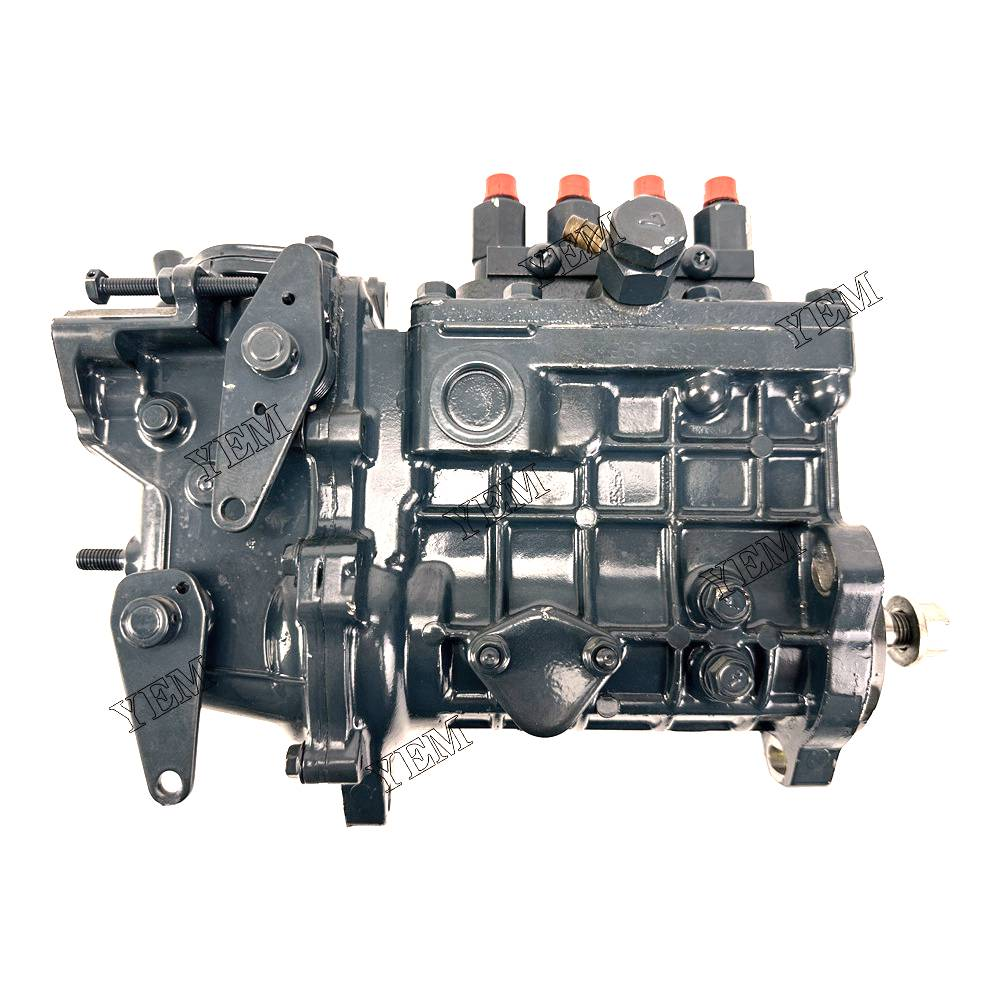

Contact us

YEM Excavator Parts Team is a dedicated and experienced team that specializes in quality parts for excavators. With our extensive knowledge and expertise in this industry, we offer a wide range of parts to meet the needs of different customers.

Our products cover all kinds of excavator parts, including hydraulic system, engine parts, chassis parts and so on. We take pride in sourcing our parts from reliable manufacturers, ensuring that each component meets the highest standards of quality and durability.

What sets us apart is our unwavering commitment to exceptional customer service. We understand the importance of timely support and our team is always available to respond to inquiries and requests in a timely manner. Our knowledgeable staff is on hand to help customers identify the correct parts for their particular excavator model and provide detailed installation and maintenance instructions.

To get in touch with our dedicated excavator parts team, feel free to contact us via our website, email or phone. We are committed to building long-term relationships with our customers and eagerly look forward to assisting you with all of your excavator parts needs.