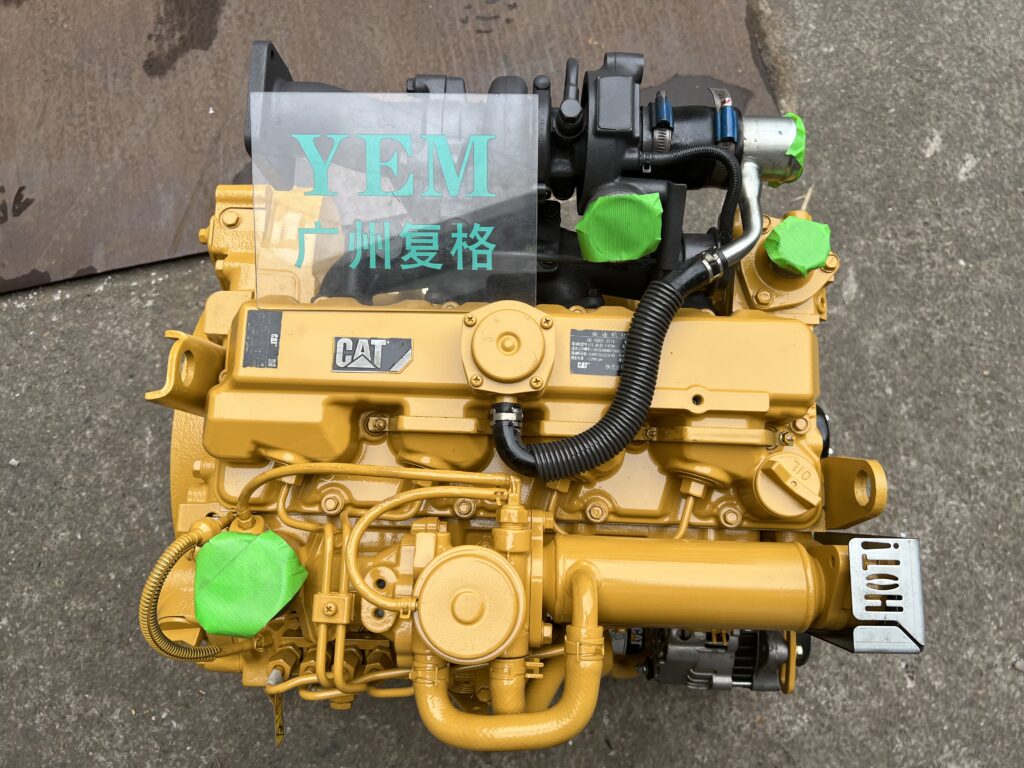

Caterpillar engine and its importance and wide range of applications

The Caterpillar engine is an engine widely used in automobiles, ships, generator sets and heavy machinery equipment. It is produced by the American Caterpillar Company. This engine adopts modern design and highly precise manufacturing process and is widely used in many important industrial and commercial fields.

As the core component of the engine, the Caterpillar engine plays a key role in ensuring the normal operation of the engine. Its efficient design and excellent manufacturing process ensure its stable performance and long life, making it the engine of choice for many automobiles, ships, generator sets and heavy machinery equipment.

Because Caterpillar engines are widely used in various fields, ensuring that they are equipped with high-quality and precise components, such as piston components, cylinder heads, fuel systems, water pumps, etc., is also crucial for the normal operation of the engine. Understanding and mastering the importance and functions of these accessories is crucial to ensuring normal engine operation, reducing failures and improving engine efficiency.

In short, the wide application of Caterpillar engines in various fields, as well as the key role and importance of this engine, make people more emphasized, understand and master the importance and functions of its accessories. Only by mastering the knowledge and skills in these aspects can we ensure the long life and efficient operation of Caterpillar engines.

Common Caterpillar Engine Parts

Here are some common Caterpillar engine parts:

- Piston Assembly: A component composed of a piston, a piston ring, and a piston pin. It is used to compress gas and push the piston to reciprocate in the cylinder, thereby rotating the crankshaft.

- Cylinder Head: The part installed above the engine block, including valves and fuel injectors, used to control the inlet and outlet of gas and the injection of fuel.

- Fuel System: A system consisting of a fuel pump, fuel injectors, fuel filters, and fuel supply lines, etc., used to supply fuel to the engine for combustion.

- Valve Train: It includes components such as valves, valve springs, and valve stems. It is used to control the opening and closing of valves to control the inlet and outlet of gas.

- Crankshaft (Crankshaft): The main shaft that connects the piston and the output drive shaft, converts the reciprocating motion of the piston into rotational motion, and drives the vehicle or other equipment.

- Intake and Exhaust System: A system consisting of an intake pipe, intake valve, air filter, exhaust pipe and exhaust valve, etc., used to introduce fresh air and discharge exhaust gases.

- Water Pump: A device used to circulate coolant to keep the engine temperature within a controllable range.

- Generator: Generates electricity to supply the power required by vehicles or equipment.

These parts are critical components in CaterBit engines and work together to ensure proper engine operation and efficient performance. Understanding the functions and functions of these common accessories will help you understand the working principle of the engine and perform maintenance and repairs.

Importance and function of parts

Caterpillar engine accessories play an important role in ensuring your engine operates properly and delivers effective performance. Here are the functions and importance of some common accessories:

- Piston Assembly: The piston is a key component in the engine. It is responsible for compressing the burning gas and transmitting power to the crankshaft through the connecting rod. The sealing performance of piston rings is crucial to the combustion efficiency and power output of the engine.

- Cylinder Head: The cylinder head is installed above the engine block and includes valves, valve seats, fuel injectors and other devices. Their normal operation ensures the smooth progress of the intake and exhaust processes, controls the combustion process and fuel injection.

- Fuel System: The fuel system is responsible for delivering fuel from the fuel tank to the engine and performing accurate fuel injection in the combustion chamber. The normal function of the fuel pump, fuel injectors and fuel filter ensures the stability of fuel supply and combustion efficiency.

- Valve Train: The valve train controls the opening and closing of valves and controls the intake and exhaust processes. Accurate control of valves is very important for adjusting combustion efficiency and power output.

- Crankshaft: The crankshaft converts the reciprocating motion of the piston into rotational motion to drive the vehicle or other equipment. Both the strength and balance of the crankshaft have an important impact on the performance and life of the engine.

- Intake and Exhaust System: The intake system is responsible for introducing fresh air, while the exhaust system is responsible for emitting exhaust gases. The design and efficiency of these systems directly affects the combustion efficiency and emissions performance of the engine.

- Water Pump: The water pump is responsible for circulating coolant and maintaining the appropriate operating temperature range of the engine. This is important to prevent the engine from overheating and improve heat dissipation efficiency.

- Generator: The generator generates electricity to provide power supply for vehicles or equipment. It is essential for the proper operation and energy supply of electrical equipment.

These accessories work together throughout the entire engine operation process to ensure proper engine operation and efficient performance. Their quality and proper functioning have a decisive influence on the engine’s life, power output, fuel efficiency and emissions performance. Therefore, knowing and understanding the importance of these accessories, as well as performing proper maintenance and replacement of them, is crucial to keeping your engine in good condition and extending its service life.

Breakdown and maintenance

Caterpillar engine failure and maintenance are key to ensuring its long-term stable operation and efficient performance. Here are some common breakdowns and maintenance issues:

- Piston ring failure: Piston rings are a critical component in the engine and are responsible for maintaining a seal between the power and the combustion chamber. If the piston rings fail, fuel and power will leak, resulting in a decrease in engine efficiency and power output. This problem can be avoided by regularly replacing the piston rings.

- Valve spring fatigue: Valve springs are responsible for controlling the opening and closing of valves. If they are not properly maintained or replaced regularly, they may fatigue or corrode, causing valve control to become inaccurate and affecting engine performance.

- Water pump failure: The water pump is very important for engine cooling. If the water pump fails, the engine may overheat and damage components such as pistons and cylinder heads, affecting engine performance. The water pump needs to be inspected and replaced regularly.

- Cylinder head erosion: High temperature environment and combustion process may cause cylinder head erosion. This will cause problems with the valves and nozzles, directly affecting engine performance. Regular maintenance and replacement of cylinder heads reduces the risk of ablation occurring.

- Electrical Problems: Generators and batteries are the most common problem components in electrical systems. Negligence and failure of the electrical system may cause the engine to fail to start or operate normally, requiring regular inspection and maintenance.

- Fuel pollution: Contaminated fuel will cause blockage and failure of the engine’s fuel system and oxidation catalytic converter. Regularly checking and replacing filters and air filters, and using high-quality fuel, can reduce the risk of fuel contamination.

The best way to maintain your Caterpillar engine is to follow the manufacturer’s guidelines and manuals for regular maintenance and inspection. Also, use suitable engine oil or lubricant and keep the engine clean to avoid malfunctions and damage. If any fault is found, appropriate measures should be taken immediately to repair it to ensure long-term stable operation and efficient performance of the engine.

How to choose and buy parts

Selecting and purchasing Caterpillar engine parts is key to ensuring parts quality and performance. Here are some suggestions for selecting and purchasing accessories:

- Priority will be given to original accessories: Priority will be given to original accessories, that is, genuine accessories provided by Caterpillar or its authorized dealers. Genuine accessories undergo rigorous quality control and testing to ensure fit and performance consistent with original equipment manufacturer (OEM) specifications.

- Accessory quality and certification: Ensure that the accessories purchased meet international standards and certifications. For example, ISO 9001 quality management system certification. These certifications indicate that the accessory manufacturer has followed certain quality standards and processes.

- Reliable suppliers: Choose reliable suppliers and dealers with good reputation and long-term experience. This ensures access to high-quality parts, reliable technical support and timely delivery.

- Warranty and after-sales service: Check whether the accessories supplier provides warranty and after-sales service. A reasonable warranty period can ensure that if there is a problem with the accessory, it will be supported and solved.

- Refer to user feedback and reviews: Read the feedback and reviews of other users to understand their satisfaction and experience with the accessories they purchased. This can provide an additional reference on the quality and performance of the accessory.

- Price Competitiveness: Compare prices from different suppliers. Note that the lowest price does not always mean the best choice. Be sure to consider factors such as quality, warranty, and after-sales service.

- Instruction Guide and Reference Manual: Refer to the Caterpillar Engine Instruction Guide and Reference Manual for information on accessory specifications, recommended maintenance and replacement intervals, and more. This will help in choosing the right accessories.

The above are some suggestions for selecting and purchasing Caterpillar engine accessories. It is important to ensure the quality, suitability and reliability of accessories to ensure proper engine operation and efficient performance.

Contact us

Our team at YEM is dedicated to providing outstanding service and support to our customers. If you have any questions or need assistance, please don’t hesitate to reach out to us using the following contact options:

We are here to help and eagerly await the opportunity to assist you with any inquiries you may have.