The role and importance of the engine oil pan

The engine oil pan, also known as the oil sump, plays a crucial role in the lubrication system of an engine. It serves as a reservoir for the engine oil and is located at the bottom of the engine.

The main roles and importance of the engine oil pan are as follows:

- Oil Storage: The oil pan holds a certain amount of engine oil that is crucial for lubricating the engine’s moving parts. It ensures a constant supply of oil, allowing smooth and efficient engine operation.

- Lubrication: The oil pan collects the engine oil and distributes it to the various engine components through an oil pump. The oil forms a thin film between the moving parts, reducing friction, wear, and heat generation. This helps to prolong the lifespan of the engine and improve overall performance.

- Temperature Regulation: The oil pan helps regulate the temperature of the engine oil. As the engine oil circulates through the engine, it absorbs heat from the moving parts. The oil pan acts as a heat sink, where the oil can cool down before being recirculated, preventing the oil from overheating and maintaining optimal operating temperatures.

- Debris Collection: The oil pan is designed with an oil pickup tube that draws oil from the bottom, ensuring that clean oil is supplied to the engine. It also acts as a collection point for any debris or contaminants that may be present in the engine oil, preventing them from entering the engine’s internal components and causing damage.

- Structural Integrity: The engine oil pan provides structural support to the engine block and contributes to the overall rigidity of the engine. It helps to reduce vibrations and noise, ensuring smooth and comfortable driving experience.

In summary, the engine oil pan is a vital component of the lubrication system, responsible for storing and distributing oil, regulating temperature, collecting debris, and providing structural support. These functions are crucial for maintaining the performance, longevity, and reliability of the engine.

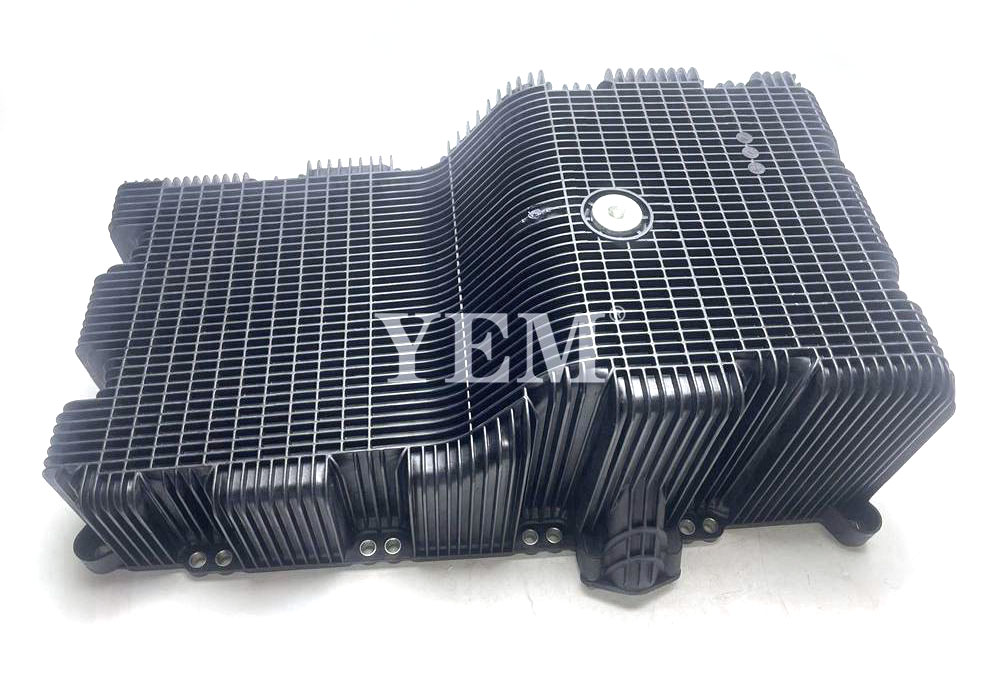

Materials and design of engine oil pan

Engine oil pans are typically made from durable and lightweight materials that can withstand the harsh conditions inside the engine compartment. The most common materials used for engine oil pans include:

- Cast Aluminum: Aluminum is a popular choice due to its lightweight nature and corrosion resistance. Cast aluminum oil pans are relatively easy to manufacture and offer good heat dissipation properties.

- Stamped Steel: Steel oil pans are commonly used in many vehicles. They are cost-effective and offer durability and strength. Stamped steel pans are usually coated with anti-corrosion materials to prevent rusting.

- Composite Materials: Some modern engines may use oil pans made from composite materials such as reinforced plastics or composites containing a mixture of plastic and fiberglass. These materials offer a combination of lightweight, durability, and corrosion resistance.

As for the design, engine oil pans are designed to fit the specific engine configurations and optimize oil flow. Here are some design considerations:

- Shape and Capacity: Oil pans are designed with different shapes and capacities to accommodate the engine’s dimensions and oil volume requirements.

- Baffle Design: Baffles are internal structures within the oil pan that help to control oil movement and prevent oil starvation during cornering or under high G-forces. They also help reduce foaming and ensure constant oil supply to the pickup tube.

- Drain Plug and Oil Level Sensor: Oil pans are designed with a drain plug for easy oil changes and maintenance. Some oil pans also have provisions for an oil level sensor to monitor the oil level and alert the driver when it is low.

- Mounting Points: Oil pans have mounting points to secure them to the engine block or subframe. These mounting points must be sturdy to ensure a secure and leak-free connection.

Overall, the materials and design of engine oil pans are essential for their function, durability, and compatibility with the engine system. Manufacturers carefully consider these factors to provide reliable and efficient lubrication for the engine.

Engine oil pan maintenance and upkeep

Proper maintenance and regular upkeep of the engine oil pan are crucial for the longevity and performance of the engine. Here are some tips to help you maintain and take care of your engine oil pan:

- Regular Inspection: Periodically inspect the oil pan for any signs of leaks, cracks, or damage. Look for oil stains or puddles underneath the vehicle, which could indicate a leak in the oil pan. If you notice any issues, address them promptly to prevent further damage.

- Oil Changes: Follow the manufacturer’s recommendations for oil change intervals and use the recommended oil type and viscosity. Regular oil changes help prevent sludge buildup and maintain optimal lubrication for the engine. When changing the oil, inspect the oil pan for any debris or contaminants that may have accumulated.

- Keep it Clean: During oil changes, clean the oil pan and remove any accumulated dirt, debris, or sludge. This helps prevent clogs and ensures proper oil flow within the engine.

- Replace Gaskets and Seals: Over time, gaskets and seals can wear out and develop leaks. If you notice oil leaks from the oil pan gasket or seals, have them replaced promptly to prevent oil loss and potential engine damage.

- Avoid Impact and Damage: Be cautious while performing maintenance or working around the engine oil pan. Avoid excessive force or impacts that could cause dents, cracks, or damage to the oil pan. Protect the oil pan from road debris or obstacles that may cause damage.

- Inspect for Proper Fitment: If you have any modifications or aftermarket components installed, ensure that they do not interfere with the oil pan or its proper fitment. Improperly fitted parts can cause stress on the oil pan and lead to leaks or damage.

- Seek Professional Help: If you are unsure about any maintenance or repairs related to the engine oil pan, it is always recommended to seek professional assistance. They can provide expert advice and ensure proper maintenance procedures are followed.

Remember, maintaining the engine oil pan is essential for the overall health and performance of the engine. By following these guidelines and addressing any issues promptly, you can help prolong the life of your engine oil pan and avoid costly repairs.

Common engine oil pan problems and solutions

While engine oil pans are generally designed to be durable, they can still develop problems over time. Here are some common issues with engine oil pans and their solutions:

- Oil Leaks: Oil leaks are a common problem with engine oil pans and can occur due to a variety of reasons such as a cracked pan, damaged gasket, or loose bolts. To fix this issue, identify the source of the leak and address it accordingly. If the pan is cracked, it may need to be replaced. If the gasket is damaged, it should be replaced, and if the bolts are loose, they should be tightened.

- Oil Pan Damage: The oil pan can be susceptible to damage from bumps, debris, or improper maintenance. If the pan is dented or has sustained physical damage, it may affect its ability to hold oil properly. In such cases, the damaged oil pan should be replaced with a new one.

- Oil Pan Gasket Failure: The gasket that seals the oil pan to the engine block can fail over time, leading to oil leaks. If the gasket is worn, torn, or damaged, it should be replaced to ensure a proper seal. During the replacement, thoroughly clean the mating surfaces of the oil pan and engine block to ensure a good seal.

- Stripped Drain Plug: The drain plug on the oil pan can become stripped or damaged, making it difficult to remove or tighten. If this happens, the drain plug should be replaced with a new one. It’s essential to ensure the new drain plug is properly torqued to prevent leaks.

- Over-tightened Oil Pan Bolts: If the oil pan bolts are over-tightened during maintenance, they can strip or break. This can lead to leaks or difficulty in removing the oil pan in the future. It’s crucial to follow the manufacturer’s recommended torque specifications when tightening the oil pan bolts to avoid these issues.

- Rust and Corrosion: Over time, the oil pan can develop rust or corrosion due to exposure to moisture or harsh conditions. If the rust or corrosion is minor, it can be cleaned and treated with a rust inhibitor. However, if the damage is extensive, it may be necessary to replace the oil pan.

- Improper Oil Level: Maintaining the correct oil level is essential for the proper functioning of the engine. If the oil level is too low or too high, it can lead to lubrication issues, overheating, or damage to the oil pan. Regularly check the oil level using the dipstick and adjust it as necessary.

If you encounter any of these problems with your engine oil pan, it is recommended to consult a professional mechanic for an accurate diagnosis and appropriate repairs or replacements. They have the expertise and tools to address the issue effectively, ensuring the optimal performance and longevity of your engine.

Engine oil pan upgrades and modifications

When it comes to engine oil pan upgrades and modifications, there are a few options you can consider depending on your specific needs and goals. Here are a few common ones:

- Baffled Oil Pans: Upgrading to a baffled oil pan can help prevent oil starvation during high-speed cornering or acceleration. Baffles are placed inside the pan to control the movement of oil, ensuring a steady supply to the engine’s vital components.

- Increased Capacity Oil Pans: If you have a high-performance engine or engage in heavy-duty tasks, upgrading to an oil pan with a larger capacity can improve oil cooling and overall lubrication. This is particularly beneficial in hot climates or during extended periods of driving.

- Oil Pan Skid Plates: Off-road enthusiasts often opt for oil pan skid plates to protect the oil pan from any damage caused by rocks, debris, or rough terrain. Skid plates provide an extra layer of armor, reducing the risk of punctures or leaks.

- Remote Oil Filter/ Cooler Kits: Installing a remote oil filter or cooler kit can improve oil cooling and filtration. These kits help regulate oil temperature, ensuring optimal performance and engine longevity, especially in demanding conditions or high-mileage situations.

- Custom Fabrication: If you have specific requirements or unique vehicle modifications, custom fabricating an oil pan to your specifications may be necessary. This allows you to tailor the oil pan design to fit your vehicle’s specific needs, such as clearance or improved oil flow.

It is essential to consult with a reputable mechanic or automotive specialist who can assess your vehicle and provide guidance on which upgrades or modifications would be most suitable for your specific situation. Remember to follow all manufacturer recommendations and guidelines to ensure proper installation and operation.

Contact us

Our YEM team comprises a skilled and passionate group of engineers and technicians specializing in excavator parts. With years of experience in the industry, we are dedicated to delivering top-quality excavator accessories and comprehensive solutions tailored to meet our customers’ needs.

We pride ourselves on our profound understanding of excavators, their working principles, and the functionalities of accessories. This enables us to provide accurate and professional recommendations to our customers. In collaboration with renowned excavator parts manufacturers and suppliers, we ensure the products we offer are of exceptional quality and reliability.

Our expertise covers all types and brands of excavators. Whether it’s replacing a damaged excavator accessory or upgrading the excavator’s function and performance, our team can provide a comprehensive solution. We consider customers’ requirements and budget to provide the most suitable accessory options while ensuring smooth installation and maintenance processes.

Beyond supplying excavator accessories, our services encompass transportation, installation, repairs, and after-sales support. Customer satisfaction is our utmost priority, and we strive to deliver outstanding service and the best solutions.

Thank you for your interest in the YEM excavator parts team. Should you have any inquiries or requirements, please do not hesitate to contact us. We look forward to providing you with high-quality excavator accessories and professional technical support.