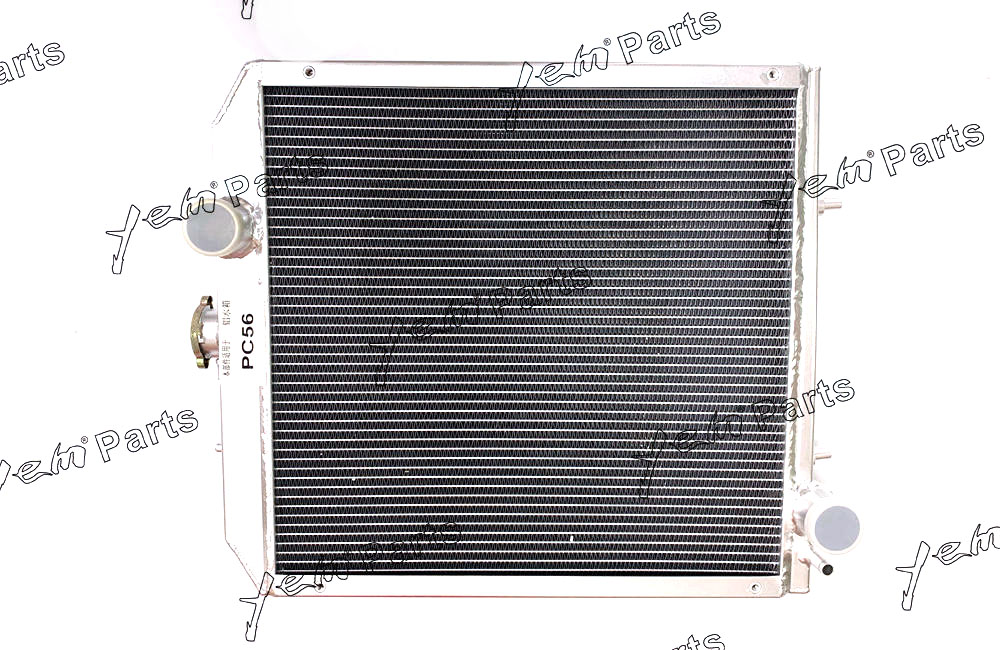

The engine radiator is a device used to regulate and control the temperature of the engine. It is usually located at the front of the engine, connected to the engine radiator, and uses a cooling medium (usually a mixture of water and coolant) to absorb and dissipate the heat generated by the engine.

The engine will generate a lot of heat energy during operation. If the heat is not dissipated in time, the temperature will rise rapidly, which may cause the engine to overheat or even be damaged. Therefore, the engine radiator plays an important role in dissipating heat and keeping the engine temperature within the normal range.

In terms of working principle, the engine water tank radiator introduces the cooling medium into the water tank, contacts the heat source, and then expands the heat dissipation area through the radiator chip and heat sink, and transfers heat to the surrounding air by means of convection and radiation. In this way, the heat in the cooling medium is gradually dissipated, so that the temperature of the engine remains within a controllable range.

The structure of the radiator of the engine water tank is generally composed of radiator fins, radiator pipes and radiator fans. The heat sink is usually composed of densely distributed fin-like structures to increase the heat dissipation area. The radiator pipe transfers heat from the engine to the radiator fins through a heat transfer medium. The cooling fan can be controlled as needed to increase the convection cooling effect.

Engine radiators are very common in the automotive industry, and are also widely used in other heat engine equipment, such as industrial machinery, generator sets, etc. With its reliable and efficient cooling performance, it helps to ensure the normal operation of engines and other equipment, and improves their life and reliability.

How the radiator works

The working principle of the radiator is based on three ways of heat conduction, convection and radiation to dissipate heat, thereby reducing the temperature of the object.

- Heat conduction: Heat conduction refers to the transfer of heat through direct contact of substances. Inside the radiator are heat transfer media (such as metal or aluminum sheet structures) that conduct heat from a heat source (such as an engine) to the surface of the radiator.

- Convection: Convection is the transfer of heat through the motion of a fluid. There is usually a fan on the outside of the radiator or the flow of a cooling system’s fluid, such as coolant in a car, that moves heat away from the surface of the radiator. Convection can be divided into natural convection and forced convection. Natural convection is the spontaneous flow of gas or liquid caused by the difference in density, while forced convection is the flow of gas or liquid driven by an external force (such as a fan).

- Radiation: Radiation refers to the propagation of heat through space in the form of electromagnetic waves. The surface of the radiator radiates heat to the surrounding environment. Radiative heat transfer mainly depends on the temperature of the radiator and the characteristics of the radiating surface, such as the color and material of the surface.

Using three methods of heat conduction, convection and radiation, the radiator can transfer heat from the heat source to the surface of the radiator, and then quickly dissipate it to the surrounding environment. By continuously cycling this process, the radiator can effectively reduce the temperature of the object and keep it within a controllable range.

In the car, the radiator of the engine water tank uses this working principle. The heat generated by the engine is transferred to the radiator through the coolant, the heat is conducted through the heat conduction medium, and then the heat is dissipated into the air by convection and radiation. Thereby keeping the temperature of the engine within the proper range.

Different types of radiators

There are several different types of heat sinks that are used in various applications, some of the common types are listed below:

- Radiator Radiator: Radiator radiators are the most common type of radiator and are widely used in automotive and industrial applications. It consists of a metal water tank and densely covered aluminum cooling fins. The coolant contacts the engine or other heat sources, conducts heat to the cooling fins, and then dissipates heat through convection and radiation.

- Air-cooled radiators: Air-cooled radiators dissipate heat through forced convection, and are usually used in fields such as electronic equipment and computers. It uses a fan to blow air across the face of the heat sink, transferring heat to the air through convection and radiation. The air-cooled radiator can be aluminum heat sink or air channel design to provide better heat dissipation.

- Liquid-cooled radiator: The liquid-cooled radiator uses cooling fluid as a heat transfer medium, and transfers heat from the heat source to the radiator through a circulation pump, and then recirculates the cooling fluid to the heat source to achieve rapid heat dissipation. Liquid cooling radiators are usually used in high-performance computers, game consoles, and supercomputers to provide more efficient cooling performance.

- Tube Radiator: The tube radiator consists of a series of metal tubes, which transfer heat from the heat source to the tubes by heat conduction, and then dissipate the heat by convection and radiation. It is commonly used in industrial and HVAC fields, such as steam radiators, tube radiators and chassis radiators.

- Chip radiator: Sheet radiator is a kind of radiator composed of dense sheet cooling fins, which is suitable for small electronic equipment and compact space. It has a large heat dissipation surface area and can dissipate heat through heat transfer media and convection.

These are just some of the common radiator types, there are actually some other radiators for special applications. Factors such as thermal requirements, space constraints, efficiency requirements, and budget need to be considered when selecting the type of heat sink that is right for a particular application.

Radiator care and maintenance

The care and maintenance of your radiator is critical to keeping it functioning properly and extending its lifespan. Here are some general radiator care and maintenance recommendations:

- Regular cleaning: Regular cleaning of the radiator can prevent dust, dirt and other impurities from accumulating and affecting the cooling effect. Dust can be gently removed from the surface of the heat sink and between the fins with a soft brush, air blower, or compressed air. Avoid flushing directly with water to prevent liquid from getting inside the radiator.

- Check the cooling fluid: If the radiator is connected to the cooling system, check the level and quality of the cooling fluid regularly. Make sure the water level is within the normal range and add or replace coolant if necessary. Pay attention to check whether the coolant is mixed with deposits or impurities, and clean and replace if necessary.

- Check fan operation: If the radiator is equipped with a fan, periodically check the fan operation. Make sure the fan spins freely without noise and vibration. If a fault or abnormal operation is found, the fan needs to be repaired or replaced in time.

- Pay attention to check the space around the radiator: the effect of the radiator is affected by the surrounding space. Make sure there are no obstructions around the radiator, such as debris, dust, or other objects, to ensure unimpeded airflow and allow the radiator to dissipate heat effectively.

- Regularly check the radiator for leaks or blockages: especially for tank radiators, regularly check for signs of leaks or blockages in the cooling pipes. If leaks or blockages are found, repair or replace damaged parts in time.

- Pay attention to the installation location and radiator protection: The radiator installation location should take into account sufficient ventilation and heat dissipation space. Also, consider installing a grid or shroud to protect the radiator from damage and collisions from external objects.

Note that specific measures for maintaining and servicing your radiator may vary by radiator type, application environment, and manufacturer recommendations. Therefore, before maintenance and maintenance, it is best to refer to the relevant manual of the radiator or consult a professional technician.

Radiator faults and solutions

Heatsinks can experience some failures, resulting in reduced cooling or complete failure. Here are some common radiator failures and their solutions:

- The radiator is blocked: If a large amount of dust, dirt or other impurities accumulate on the surface of the radiator or on the heat sink, it will hinder the air flow and reduce the heat dissipation effect. The solution is to clean the radiator regularly, using a soft brush, air blower or compressed air to gently remove dust and grime.

- Fan failure: If the radiator is equipped with a fan, the fan may malfunction, such as not rotating, excessive noise, etc. The solution is to check the fan’s power connection and wiring to make sure it’s working properly. If the fan is damaged, it needs to be replaced with a new one.

- Water leakage: For the water tank radiator, water leakage may occur. Water leaks can be caused by aging seals, broken or corroded pipes. Solutions include inspecting and replacing damaged seals, patching or replacing damaged piping, and making sure the coolant in the cooling system is at the proper level.

- Radiator damage: The fins, pipes, or other parts of the radiator may be physically damaged, such as bumped, twisted, or broken. The solution is to repair or replace damaged parts, depending on the extent of the damage. It is important to note that severely damaged radiators may require complete replacement.

- Radiator installation problems: Incorrect installation of the radiator, restricted space or lack of ventilation can also affect its cooling effect. The solution is to reinstall the radiator, making sure it gets enough room for ventilation and cooling. Consider changing to a more suitable radiator type to suit specific installation conditions.

- Cooling system failure: Sometimes, the failure of the radiator may also be caused by the failure of other components of the cooling system (such as water pumps, coolant pipes). Solutions include checking and repairing other possible faulty components in the cooling system.

If you encounter a radiator failure, especially a serious failure, it is recommended to seek the help of a professional technician to ensure that the problem can be properly diagnosed and resolved.

Ways to Optimize Radiator Performance

There are several approaches you can take to optimize the performance of your heat sink:

- Increase the heat dissipation surface area: the heat dissipation effect of the radiator is directly proportional to its surface area. By increasing the heat dissipation surface area of the heat sink, the conduction and dissipation of heat can be increased. For example, more fins can be used or the density of the fins can be increased to increase the surface area.

- Improve the heat sink material and structure: choose materials with good thermal conductivity, such as aluminum, copper or other high thermal conductivity materials, to improve the heat dissipation effect of the radiator. Optimizing the structural design of the heat sink, such as increasing the gap between the heat sinks or adopting a thin sheet structure, can also increase the heat dissipation effect.

- Improved air flow: Optimizing air flow can improve the convection cooling effect of the radiator. Make sure there are no obstructions around the radiator and keep the ventilation open. Fans or air ducts can be used to increase air flow and improve the cooling effect of the radiator. Adjust the speed and position of the fans to suit different heat dissipation requirements.

- Use cooling liquid cooling system: Liquid cooling system can provide higher heat dissipation efficiency than air cooling system. The liquid cooling system transfers heat from the heat source to the radiator through a circulation pump, and then recirculates the coolant to the heat source to achieve rapid heat dissipation. Liquid cooling systems are suitable for high power equipment and applications requiring higher thermal performance.

- Plan the radiator layout: When designing and installing the radiator, consider the exact radiator layout and location to minimize the heat transfer path between it and the heat source. Make sure there is enough contact surface between the heat source and the heat sink to maximize heat transfer.

- Control the ambient temperature: Maintaining a suitable ambient temperature around the radiator can improve the effect of the radiator. Make sure there are no other heat sources around the radiator to avoid the impact of high temperature environment on heat dissipation performance.

To sum up, by increasing the heat dissipation surface area, improving the material and structure, improving the air flow, using liquid cooling system, planning the layout and controlling the ambient temperature, the performance of the heat sink can be optimized and its heat dissipation effect can be improved. When optimizing heat sink performance, it is recommended to choose the appropriate method based on the specific application needs and heat sink type.

The future development trend of radiators

As a key component of thermal management technology, heat sink has some future development trends in continuous development and innovation. The following are several possible directions for the future development of radiators:

- High-efficiency heat dissipation materials: Future heat sinks may use more efficient heat dissipation materials, such as composite materials with high thermal conductivity, nanomaterials, or materials with special heat conduction properties. These materials can provide better thermal conductivity and increase the heat dissipation efficiency of the heat sink.

- Second-order heat pipe technology: The second-order heat pipe is an emerging thermal management technology that can provide higher heat transfer efficiency in the heat sink. Future radiators may use second-stage heat pipe technology to make heat conduction faster and more uniform, and improve heat dissipation performance.

- Intelligent heat dissipation control: With the development of the Internet of Things and artificial intelligence technology, future radiators may have intelligent heat dissipation control functions. For example, according to temperature and load changes, it automatically adjusts fan speed and radiator operating mode to achieve intelligent thermal management, improve energy efficiency and reduce noise.

- Enhanced heat sink design: Future heat sinks may be designed with more focus on optimization of heat conduction and heat distribution. Using more complex fluid dynamics simulations and advanced fluid channel designs, better heat transfer and enhanced heat dissipation can be achieved.

- Radiator combined with energy recovery: In order to improve energy efficiency and sustainability, future radiators may be combined with energy recovery technology. For example, the heat of the radiator is converted into usable energy, such as power generation or heating, thereby realizing the reuse of energy.

- Personalized cooling solutions: With the advancement of technology, future radiators may pay more attention to personalized cooling solutions. According to different application requirements and equipment characteristics, custom-designed radiators provide more accurate and efficient cooling effects.

These are some possible trends and directions for the future development of radiators. With the continuous advancement and innovation of science and technology, radiators still have a broad space for development in the field of thermal management to meet the increasing demand for thermal management.

Contact us

Our YEM team is composed of a group of experienced, enthusiastic and professional excavator parts engineers and technicians. We are committed to providing customers with high-quality excavator accessories and related solutions to meet customer needs.

Our team has many years of industry experience and is familiar with all types and brands of excavators. We have an in-depth understanding of the working principle of excavators and the functions of accessories, and can provide customers with accurate and professional suggestions. We cooperate with many well-known excavator parts manufacturers and suppliers to ensure that the products we provide to our customers are of high quality and reliability.

Whether it is necessary to replace a damaged excavator accessory or to upgrade the function and performance of the excavator, our team can provide customers with a comprehensive solution. We can provide the most suitable accessory options according to the needs and budget of customers, and ensure the smooth progress of installation and maintenance work.

Our services are not limited to providing excavator accessories, but also include transportation, installation, repair and after-sales support of accessories. We always take customer satisfaction as our primary goal and strive to provide customers with excellent service and the best solutions.

Thank you for your interest in Yem excavator parts team, if you have any needs or questions, please feel free to contact us. We look forward to working with you to provide you with high-quality excavator accessories and professional technical support.